Practical and efficient manure management on animal farms is important to ensure smooth operation, provide valuable nutrients to crop production, and minimize the negative impact on environment. However, manure management can be challenging for farmers due to extreme weather events and increasing size of animal operations. Many animal operations in certain regions are competing for limited crop fields and workable days for land application. Under certain circumstances, some animal farms would need additional manure treatment and transportation, resulting in increased management and costs for manure treatment, storage, and land application.

Anaerobic lagoons are commonly used for the storage and treatment of swine manure in the US, especially for older pig farms. This method is suitable for storing low solid manures for farms with liquid manure handling systems, such as a flushing system and a pull-plug system. The anaerobic lagoons allow the manure to be stored and treated in a low-oxygen environment, which promotes the growth of anaerobic bacteria that break down the organic matter in the manure.

However, a significant amount of residual solids can accumulate in the lagoon and form sludge over time. If the sludge is not managed properly, it can affect treatment performance of the lagoons due to reduced treatment volume. If the lagoon treatment volume is undersized or the farm has expanded, the sludge can also accumulate faster. The costs associated with desludging, hauling, and land applying the sludge can be significant and burdensome for swine producers with anaerobic lagoons with sludge buildup. Also, anaerobic lagoons are often associated with other challenges, like odor nuisance and significant nitrogen nutrient loss.

To promote environmental stewardship, odor control, nutrient conservation, and economic value of flushed manure, additional steps can be incorporated into an existing manure management system. One Missouri pig finishing farm installed an aboveground slurry tank as an additional manure storage component as a way to conduct solid-liquid separation prior to lagoon storage, thus improving the effectiveness of the overall manure management system. The aboveground slurry storage tank was equipped with an agitation system that enabled thorough mixing to ensure homogenized manure nutrients for crop field application and improve fertilizer savings due to a more uniform manure nutrient source.

Generally, aboveground slurry tanks are selected in manure management scenarios that have limited storage capacity, inconsistencies in the nutrient contents, and/or inadequate and expensive desludging processes. This case study aims to demonstrate how an aboveground slurry tank system can be adapted to an existing lagoon system to maximize the nutrient value of the manure and provide guidelines on the cost and management of the system. Incorporating aboveground slurry tanks would ultimately result in some flexibility and improve manure solid separation prior to lagoon storage. Separated manure slurry typically has a high concentration of nutrients allowing for less synthetic fertilizer use and encourage more manure applications on nearby crop fields needing the nutrients and carbon, resulting in a positive return.

Swine farm and aboveground manure slurry storage system

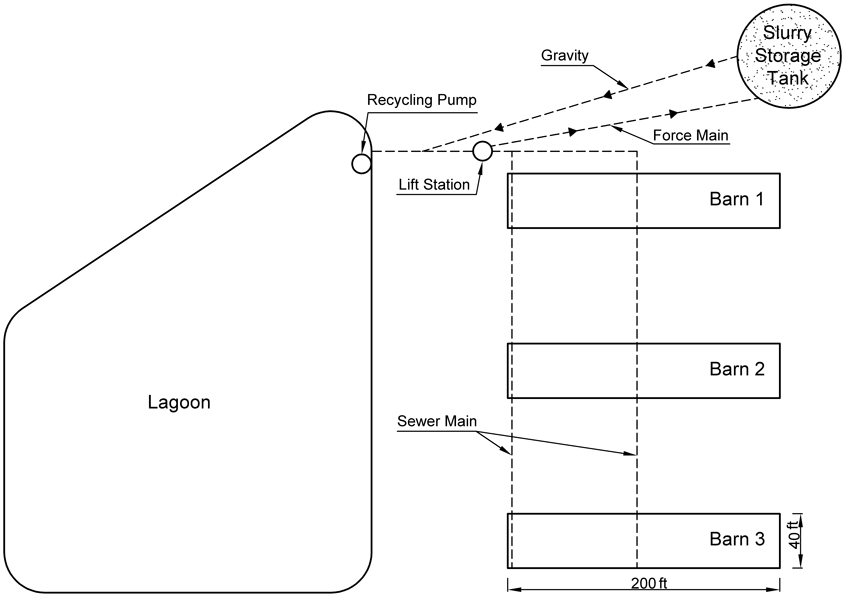

A commercial swine farm located in Missouri, had three identical finishing barns with a total capacity of 2,880 head of finishing pigs. The layout of the farm with anaerobic lagoon and aboveground slurry storage tank is shown in Figure 1. The three finishing barns were built in 1994 and the aboveground slurry storage tank was built in 2013. The dimensions of each finishing swine barn were 200 feet (L) × 40 feet (W). The finishing hogs were confined on concrete slatted floors with 1-inch slot width above 2-foot shallow concrete pit (the total volume of the shallow concrete pit was about 16,000 cubic feet). A manure pull-plug system was used to remove the swine manure in each barn every three weeks (one barn per week) into a collection pit outside of the barns. The farm staff would typically drain only barn every week, so that the lagoon was loaded once per week for consistency.

According to the ASABE standard1, each grow-finish swine (average weight of 154 pounds) produces about 1.25 gallons of total manure every day, which amounts to a manure volume of 1.24 million gallons per year at this farm (assuming 345 d operational barns, about three weeks per year empty due to maintenance and cleaning times in between growth cycles). Animal Waste Management software (AWM Version 2.4, USDA 2023) was used to estimate the lagoon volume needed to match the animal type, capacity, and local weather2. The lagoon volume calculated by AWM was 10.3 million gallons with the assumptions of 10 years sludge accumulation period and no newly introduced washing and flushing water.

Before the installation of the aboveground storage tank, this farm relied solely on its anaerobic lagoon to store and treat the swine manure for later land application at nearby crop fields. The lagoon was trapezoid with two parallel heights (lengths) of 200 and 380 feet, and a width (base) of 280 feet. The side slope of this lagoon was approximately 3-to-1 and depth was 15 feet. Based on the above size, the total volume of this lagoon was approximate 6.8 million gallons. Due to a lack of proper storage volume (6.8 million gallons vs. 10.3 million gallons needed according to the calculation of AWM software), the lagoon experienced rapid sludge buildup, necessitating frequent desludging and off-farm transportation of the sludge. To address this issue, the farm sought a simple and low maintenance manure solid separation system that would reduce solids entering the anaerobic lagoon and provide additional waste storage capacity.

The farm worked with local USDA NRCS team and evaluated several manure storage and treatment options. The farm constructed a 635,000-gallon aboveground slurry store tank (shown in Figure 2) that could hold approximately an additional 180 days of manure storage capacity. The farm reported that it usually took about three months to fill the aboveground slurry tank (instead of six months) due to the recharged water (about 2-inch depth of recycled water) added to each barn. The choice of the slurry tank was based on the capital and maintenance considerations, and the USDA NRCS Environmental Quality Incentives Program (EQIP) partially funded the installation of this system. Additionally, the system was designed to allow for more consistent effluent for crop nutrients through the agitation system for maximum fertilizer value and conformed to USDA-NRCS recommendations. In this study, we examined the installation and operation of the slurry tank and assessed its impact on swine manure nutrient management due to the addition of the aboveground slurry tank.

Manure management system

Recycled water from the lagoon was pumped to the 2-foot concrete pit to dilute (recharge of 2-inch depth after draining) the fresh manure. Before the construction of the aboveground slurry tank, dilute manure was draining from the concrete pits and flowing through an 8-inch drain sewer pipe (acting as a pull plug system) to the collection pit outside of the barns. Then the dilute overflow manure would flow continuously to the nearby anaerobic lagoon by gravity. A recycling pump at the lagoon was used to recycle lagoon effluent from near surface of lagoon water to the barns. The plug in each barn was pulled once every three weeks so that the manure storage time was about three weeks for each of the three barns.

To incorporate the slurry tank into the manure management chain, a lift station was constructed near the collection pit to pump the gravity drained manure into the slurry tank. With the modifications, gravity drained manure in the collection pit would flow into the lift station (Figure 3) by gravity. The lift station was equipped with a 10 hp pump at the bottom, which was accessible through a 4-foot × 4-foot hatch and a 14-foot deep manhole. The submerged pump was mounted on a crank, which allowed for easy maintenance by raising the pump out of the manhole.

When the aboveground slurry storage tank reached capacity, a weir-like structure facilitated the siphoning of supernatant off the top portion of the slurry tank into the lagoon, while the settled solids and thicker slurry portion remained at the lower section of the tank. Additionally, a safety overflow was installed at the lift station, which could divert gravity drained manure directly into the lagoon through an 8-inch sewer pipe in case the submerged pump was malfunctioning, or the lift station needed maintenance. Prior to pumping out the slurry tank, the stored slurry was first agitated and then transported off-farm to neighbors’ nearby crop fields for land application using a GEA Houle 7,300-gallon applicator tank. A private custom manure hauler was contracted and responsible for emptying the anaerobic lagoon when needed.

The anaerobic lagoon, which was still an important component of the manure handling system of this farm, was the last and final storage of the manure management system (Figure 4). Even with the additional slurry tank, mineral and sludge build-up still accumulated in the lagoon over time3, and the build-up reduced the lagoon’s treatment and storage volumes, thus desludging of the lagoon was still needed.

Details on the lagoon sludge characteristics, frequency of sludge agitation and pumping out, and land application were not included in this publication, because the scope is to characterize the effectiveness of the slurry tank in removing manure solids. The farmer emphasized, however, that including an aboveground slurry tank in the manure management system reduced the frequency and costs of desludging the anaerobic lagoon. It should also be noted that the recycled water was used to recharge the building shallow pits (one pit per week), thus it was important to ensure very low solid content lagoon water/effluent for recycling to pits.

Prior to agitating the aboveground tank, samples from the manure lift station, slurry tank, and lagoon surface were taken in the Spring of 2021 (05/06/2021) as preliminary analysis of the differences between the source and storages. To characterize the effect of the aboveground slurry tank storage on the nutrient and solid contents, multiple slurry tank effluent samples were collected to compare with total solid production of the farm. Specifically, seven effluent samples were taken during the three-day pumping out process and analyzed for the major crop nutrients and solid contents. These test results were used to characterize the potential solids removal of the aboveground slurry tank. Effluent samples of the slurry tank were collected during the Fall land application events in 2021 and 2022. All effluent samples were sent to University of Missouri Soil and Plant Testing Laboratory for analysis.

Aboveground slurry tank system and operation

The aboveground slurry tank was a glass-fused-to-steel aboveground circular tank (CST Industries, Inc.) with built-in agitation provision (Figures 2 and 5) to enable homogenous mixing of the manure during emptying. The aboveground slurry tank also had relatively smaller surface area to storage volume compared with lagoon storage, thus exposing less manure to the air/oxygen. The forming of a crust layer (Figure 6) on the manure surface during storage in the slurry tank helped with odor management. According to the slurry tank vendors, the ability to agitate its entire contents distinguished this slurry storage system from lagoons and concrete pits. They further emphasized that the tank would result in more consistent nutrients in effluent by using its central agitation system to mix the manure solids and nutrients more evenly.

The aboveground slurry tank measured 78 feet in diameter and 19 feet in height and was equipped with a 12-inch underground pipe in the center of the bottom of the tank for manure loading and recirculation for agitation. Check valves and safety valves were also included on the feeder pipe. A centrifugal pump (1,520 rpm impeller, 6,000 gal/min, 265 feet. head pressure) (Figure 7) was side-mounted onto the tank foundation, which was used for agitation and emptying. A tractor PTO was used to operate the pump, the manufacturer recommended a tractor size of 80 to 120 horsepower. The agitation system consisted of a center agitator nozzle and an over-the-top nozzle. The center agitator was a floor-mounted agitation nozzle that recirculated and agitated the slurry. The agitator was operated by a slider lever that could rotate the nozzle 360 degrees, allowing the jet agitation to be pointed any direction along the tank’s bottom.

The centrifugal pump was fitted with a two-way valve and a slider valve (Figure 7). The various combinations of these valves enabled loading the slurry effluent into the spreader tank, agitating the tank from the floor, and diverting the flow to the top agitator nozzle to break the surface crust.

Characteristics of the slurry effluent samples

Characteristics of the slurry samples collected from the lift station, slurry tank effluent, and lagoon (May 6, 2021) are shown in Table 1. Concentrations of nitrogen, phosphorus (as P2O5) and potassium (as K2O) were 48.4, 32.7 and 10.1 pounds per 1,000 gallons, respectively. The total nitrogen in the slurry tank was 42% lower than that in lift station and ammonium-N and phosphorus were lower by 5% and 62%, respectively. On the other hand, potassium, pH, and electrical conductivity were 39%, 7%, and 14% higher than those in lift station, respectively. It was also noted that the moisture content of the tank effluent samples was 96.9%, or 3.1% total solids. The lift station sample had a greater solid and nutrient contents, which could have been due to lack of replicated samples, because the sampling was not conducted specifically during a gravity draining of pit event.

Table 1. Characteristics of slurry samples collected at various points of the manure management system.

| Tests | Units | Lift station | Tank effluent | Lagoon |

|---|---|---|---|---|

| Nitrogen (N) | lb./1000 gal | 48.4 | 28.0 | 5.8 |

| Ammonium (NH4+-N) | ppm | 1,850 | 1,751 | 622 |

| Phosphorus (P) | lb P2O5/1000 gal | 32.7 | 12.3 | 1.5 |

| Potassium (K) | lb K2O/1000 gal | 10.1 | 14.0 | 12.0 |

| Moisture | % | 87.6 | 96.9 | 99.4 |

| pH | 6.59 | 7.07 | 7.74 | |

| Electrical conductivity (EC) | mmho/cm | 5.12 | 5.86 | 3.33 |

Results (Table 1) of the nutrient contents in the tank effluent were slightly less than expected from typical deep-pit slurry, as we expected the values to be greater after the slurry was stored longer and agitated. We expected the total solid content (3.1%) of the slurry sample to be less than that of gravity drained manure. Regardless, the results suggest that the slurry tank was in general performing as a settling basin, which reduced the nutrients and solids components of the barn effluent going into lagoon. We then coordinated with the farm to collect more samples during the subsequent tank agitation and emptying seasons in the falls of 2021 and 2022.

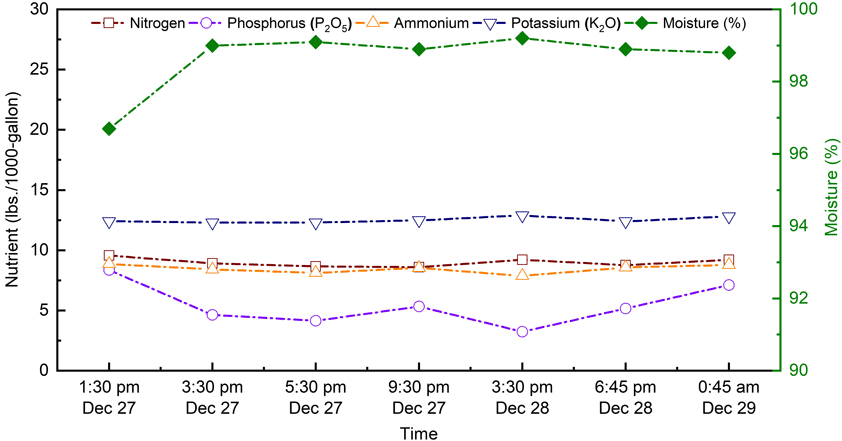

Sampling of slurry effluent was conducted in the fall of 2021 during the agitation and pumping out of the slurry tank. The samples were obtained multiple times during each of the land application days. As shown in Figure 8, the total solid concentrations observed in both the spring 2021 and fall of 2021 samples were relatively low, not as expected from an agitated slurry storage system. The nutrient concentrations, including nitrogen, phosphorus (P2O5), ammonium (NH4+-N) and potassium (K2O), were also equally low, due to the low solid content. Communication with the farm and the neighbor who operated the slurry tank agitation confirmed that the team was not operating the agitation consistently, and no agitation was conducted prior to the pump out. The lack of consistent and low efficiency of agitation during pumping out may have also contributed to the lower solids and nutrient contents.

Typically, swine slurry, especially that have settled for a period, is expected to have total solid concentrations of 10% and greater4. The high solids concentrations are often associated with high nutrient concentrations. This greater nutrient concentration would thus make economic sense to pump-out the slurry tank and use the slurry as a crop fertilizer. In comparison, the slurry from a deep pit system has been reported to have approximately 7% total solids5 and 58, 48, 29 pounds of nitrogen, phosphorus (as P2O5), and potassium (as K2O) per 1,000 gallons, respectively. However, the low solid and nutrient contents in the 2021 samples prompted concerns if the samples were representative and how effective it was agitated. These factors would heavily affect the characteristics of the slurry. More samples were then collected in the following year to confirm and understand the characteristics of the slurry tank operation.

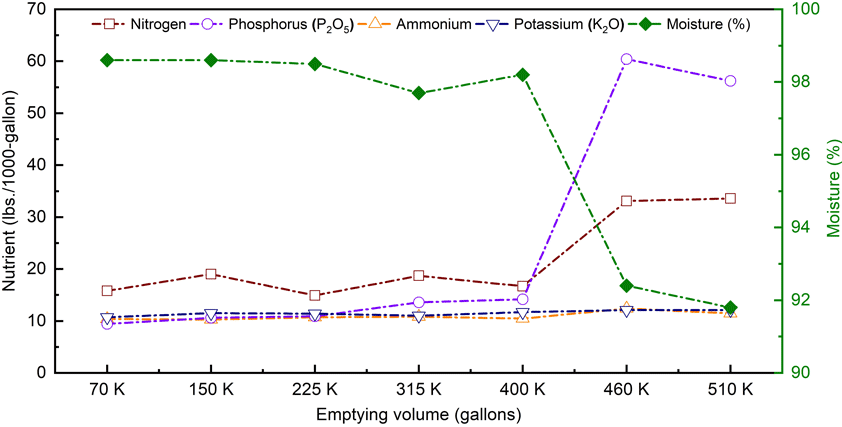

Sampling of the slurry effluent was conducted again in the fall of 2022 during the pump out event of the slurry tank. The samples were obtained at various pump out volumes of the land application days. As shown in Figure 9, both the total solids and nutrient concentrations are relatively low at the beginning of the pump out process, while the nitrogen, phosphorus and total solids increased towards the end of the process, after about 400 K of effluent was pumped. The large differences of the solids and nutrients during the pumping out is undesirable to the land application, implying more consistent and pre-agitation of the slurry agitation is needed. However, the greater solid and nutrient contents of the last two effluent samples also confirm that the slurry tank was actually storing significant amounts of settled solids and nutrients at the lower portion of the tank. In additional, more attention is needed to make sure the stored slurry is well agitated before pumping out for more consistent nutrients for the land applications.

To estimate the solids retained by the slurry tank, average solid contents of the effluent samples and the total effluent pumped out were applied to calculate the total amount of solids in the pumped out. We estimated 570K gallons of the effluent was pumped, which was 90% of the capacity of the slurry tank. Similarly, not all slurry would be pumped out of a deep-pit system for land application. According to the ASABE standard of Manure Production and Characteristics1, this commercial swine farm produces 175,200 cubic feet (1,309,826 gallons) total manure and 686,200 pounds. (82,401 gallons, using water density) total solids per year. The total solids in the aboveground slurry tank were estimated as 23,660 gallons with segmented calculation. According to the management system of the aboveground slurry tank, the tank was pumped out every 180 days (six months). That means the volume of total solid stored in the aboveground slurry tank is about 47,320 gallons per year, which is almost 57.4% of the annual total solids.

The results also suggest that the aboveground slurry tank was not trapping as many solids and nutrients as was expected. In addition, the tank might have created anaerobic treatment conditions similar to the anaerobic lagoons, which aids breaking down the solids. It was not known how much thicker the last amount of the slurry was. Collecting additional samples from the slurry portion not pumped at a future pump out event would provide valuable information. A challenge is that there might not be enough volume left for proper agitation to collect a representative sample.

Capital costs of the aboveground slurry storage system

Capital costs of constructing the 635,000-gallon aboveground slurry tank were obtained from the farm and construction engineers. Total cost of the slurry tank system was $180,327 in 2012. The costs of installing the slurry system included purchasing the tank, agitation system, and lift station pump, as well as labor and miscellaneous expenses. Table 2 provides a detailed breakdown of the costs, including foundation design, engineering fees, metal and concrete works, and freight charges. However, the costs do not include site preparation, soil testing, applicable taxes, and electrical work. It is worth noting that the system came with a five-year manufacturer’s warranty. While operational costs were not calculated, it is inevitable that pumps and other equipment will require some maintenance. Fortunately, the maintenance costs are expected to be relatively low since agitation is only necessary before the annual pump out and land application.

Table 2. Capital costs of the slurry tank system components (values of 2012).

| Item | Cost |

|---|---|

| Slurry tank (78 ft dia. × 19 ft H) | $ 90,572 |

| Side-mounted pump and agitation system | $ 29,489 |

| 10-HP lift pump | $ 16,600 |

| Labor costs | $ 39,862 |

| Misc. expenses | $ 3,804 |

| Total | $ 180,327 |

Conclusion

Manure management is an important consideration on all livestock operations. The increased size of operations in swine production systems in many concentrated areas has resulted in the generation of more swine manure than can be effectively utilized on the available nearby land base. As a result, the farms frequently store, and land apply manure to neighboring fields that are further away, necessitating more extensive storage facilities and raising the cost of manure transportation due to longer distances. Anaerobic lagoons are commonly used for storing and treating swine manure. Incorporating an aboveground slurry tank into the swine manure management system would potentially reduce the lagoon emptying costs while providing a relatively low cost and nutrient-consistent slurry for land application. This case study documents a swine farm that added an aboveground slurry storage tank as additional manure storage and ways to retain slurry with higher solids and nutrients. At a capital cost of $180,327 (2012 dollar value), the swine farm was able to add over 0.63 million gallons of storage and treatment capacity, and potentially reduce the sludge accumulation in the lagoon, reduce the odors, and work with neighbors to land apply the slurry effluents as crop fertilizers. This exporting of nutrients to neighbors consequently reduced the costs of desludging the lagoon, increased lagoon treatment efficiency, and facilitated land application on neighboring crop fields and ultimately improved manure nutrient management.

Disclaimer

Mentioning the product model, brand name, and information in this publication are solely for readers’ general interest and convenience and do not suggest any endorsement by the authors and the University of Missouri.

Acknowledgement

The authors appreciate the help of the farm management team.

References

- ASABE. ASAE Standard D384. 2005, Manure Production, and Characteristics.

- USDA Animal Waste Management Version 2.4.1.

- Canter, T., Lim, T.-T., Chockley, T. 2020. Considerations of Pull-Plug Sedimentation Basin for Dairy Manure Management. University of Missouri Extension.

- NRCS-USDA. 2009. Agricultural Waste Management Field Handbook.

- Jeffery C. Lorimor, Kris Kohl. 1998. Liquid Swine Manure Nutrients (PDF).