A septic tank/absorption field is the most common onsite sewage treatment system in use in Missouri. Nearly 30 percent of all housing units in Missouri use onsite wastewater treatment systems most of these are septic tank/absorption field systems. Several surveys throughout the state have shown that 70 percent, or 150,000, of these systems are not functioning properly. Based on the General Soils Map of Missouri, counties in the Missouri Ozarks are particularly at risk. Depending on the county, 60 to 99 percent of the soils show severe limitations for using absorption field systems.

Human contact with sewage is a serious public health risk. Drinking water contaminated with sewage can cause health problems such as diarrhea, nausea, cramps, dysentery and hepatitis. Exposure to sewer gases can also cause discomfort and illness.

For at-risk areas, connecting to an adequate public sewer system is generally the best alternative for disposing of domestic sewage from private residences. Where access to a public sewer system is unfeasible or too expensive, proper siting and design of an onsite sewage system is critical to avoid its premature failure. In many situations, an existing system that is failing may not be "repairable." Thus a completely new system may be needed. Misuse of individual sewage systems results not only in water quality problems and nuisance conditions, but also in costly repairs to rehabilitate a failing system. Failing systems include both those that you can see and smell and those that seep effluent, or waste liquids, into groundwater supplies before the soil can properly remove disease-causing pathogens.

To reduce public health risks and protect drinking water supplies, state legislation that took effect Jan. 1, 1996, sets minimum construction, design and permitting standards for onsite sewage systems. Individual counties may adopt stricter standards than those outlined by the state legislation. To ensure compliance with local codes and to reduce their environmental liability, homeowners should consult with their county health department sanitarian or building regulations department prior to new construction or repair of any onsite sewage system.

For counties that have adopted the state standards without modifications, homeowners with single family residences on lot sizes of less than 3 acres must obtain a county permit before beginning construction of any sewage system.

How does a septic tank/absorption field system work?

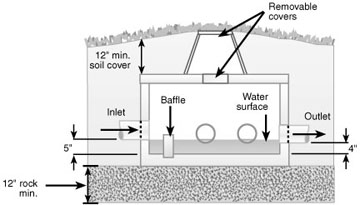

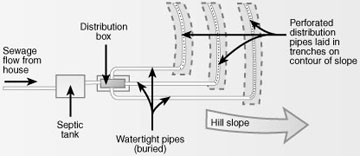

A septic tank system consists of three major components: the septic tank, a distribution device and an absorption field. A septic tank is a large, watertight, corrosion-resistant, buried container that receives raw sewage from the plumbing drains of the home. In it, solids are separated out of the raw sewage and are partially digested by anaerobic (oxygen-lacking) bacteria.

The septic tank must be large enough to allow retention of the raw sewage and some decomposition for at least 48 hours. Solids that are not digested either float to the top to form a scum layer or settle to the bottom of the tank as sludge. Depending on tank size and sewage volume, the sludge and scum must be pumped out at least every 2 to 5 years to allow bacterial digestion to continue in the tank. Otherwise, raw sewage may flow directly through the tank and into the absorption field, causing its failure.

After primary treatment in the septic tank, the liquid effluent flows through the distribution device, which ensures that equal quantities of effluent go to each pipe in the absorption field. The absorption field is a subsurface leaching area within the soil that receives the liquid effluent from the distribution device and distributes it over a specified area where it is allowed to seep into the soil. The filtering action of the soil, combined with further bacterial action, removes disease organisms and treats the harmful material in the effluent, completing the treatment process so that the water is recycled to the surface or groundwater source.

If properly designed, installed and maintained, a septic tank system can effectively treat household wastewater for more than 20 years. All design and construction must be in accordance with Missouri Department of Health (DOH) Rule 19 CSR 20-3.060, Minimum Construction Standards for On-Site Sewage Disposal Systems.

Site selection

Many Missouri soils have a high clay content, which makes them poor absorbers of septic tank effluent and may prevent the use of a septic tank/absorption field system. In addition, southwest and south central Missouri are particularly vulnerable to groundwater contamination because soils are extremely porous due to cherty gravel and/or fractured bedrock below the clay topsoil.

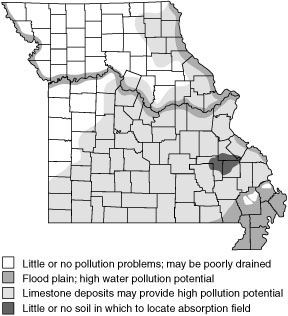

Figure 1 shows areas where potential groundwater pollution may restrict location of the absorption field. If you live in one of these areas, or if you are not sure of the pollution potential from your proposed system, seek professional help with your site selection. Help is available through your local Department of Health office, MU Extension center, Natural Resources Conservation Service office or the Missouri Division of Geology and Land Survey in Rolla, Mo.

Figure 1

Figure 1

Areas where potential groundwater pollution may restrict location of absorption field.

Table 1 shows the minimum setback distances that must be observed for septic tanks and absorption fields. On small or restrictive lots, a good way to locate the site for the system is to make a scale drawing of the site, marking out areas that are off-limits according to Table 1 and leaving the remaining open areas as potential system locations. To ensure adequate room for the eventual replacement of the new or existing septic system, identify a location for an alternate system.

Table 1

Setback distances for sewage tanks and disposal areas

| Minimum distance in feet from: | Sewage tanks1 | Absorption fields2 |

|---|---|---|

| Private water supply well3 | 50 | 100 |

| Public water supply well | 300 | 300 |

| Cistern | 25 | 25 |

| Spring | 50 | 100 |

| Classified stream, lake or impoundment4 | 50 | 50 |

| Stream or open ditch5 | 25 | 25 |

| Property lines | 10 | 106 |

| Building foundation | 5 | 15 |

| Basement | 15 | 25 |

| Swimming pool | 15 | 15 |

| Water line under pressure | 10 | 10 |

| Suction water line | 50 | 100 |

| Upslope interceptor drains | 10 | |

| Down-slope interceptor drains | 25 | |

| Top of slope of embankments or cuts of 2 feet or more vertical height | 20 | |

| Edge of surficial sinkholes | 50 | 100 |

| Other soil absorption system except repair area | 20 |

1Includes sewage tanks, intermittent sand filters and dosing chambers.

2Includes all systems (sand filter, wetland and the like), except wastewater stabilization lagoons.

3Unplugged abandoned wells, or wells with less than 80 feet of casing depth shall have 150-foot minimum setback distance from all above.

4A classified stream is any stream that maintains permanent flow or permanent pools during drought periods and supports aquatic life.

5Sewage tanks and soil absorption systems should never be located in the drainage area of a sinkhole.

6Recommend 25 feet of downslope property line initially, but repair may be allowed to 10 feet of downslope property line.

Determining soil suitability

The absorption field provides final treatment of the wastewater, so it is critical to have uncompacted, unsaturated soil surrounding the soil treatment system. The effluent leaving the septic tank contains viable pathogenic organisms. The soil's purpose is to destroy these pathogens, treat and degrade organic materials, and act as a physical, chemical and biological filter to purify the effluent and make it acceptable quality for groundwater. Soils must be capable of absorbing the volume of wastewater from the septic tank at all times of the year.

With more than 400 different kinds of soils in Missouri, it is likely more than one type will be found on even a small lot. Because many of these soils are unsuitable for conventional gravel trench absorption fields, two methods — soil morphology evaluations and percolation tests — are commonly used for sizing the absorption field.

Soil morphology evaluations

Soil morphology evaluations are preferred for sites where soil conditions suggest a potential pollution risk to groundwater. In Missouri, these evaluations may only be done by individuals approved by the Department of Health. This includes soil scientists or persons completing specific schooling and field practice requirements in soil morphology. A current list of qualified soil scientists is available from your county health department sanitarian.

Soil morphology evaluations are done by digging one or more 4- to 6-foot deep soil pits using a backhoe. The soil scientist then examines the soil profile for its texture, color, structure, mottling and rock fragment characteristics and assigns a "loading rate" in gallons per day per square foot for that particular site location. The soil scientist will also provide a site plan, showing major topographical features such as streams and drainage patterns and locations for proposed buildings. The recommended trench depth for the absorption field will be specified and, if needed, the methods for diversion of surface and subsurface water flow.

Since soils can be quite variable even 50 to 100 feet apart, it is wise to dig several pits for evaluation of the best site. Soil morphology evaluations are preferred in the Missouri Ozarks because they are more reliable, more informative and generally less expensive than percolation tests.

Percolation test procedure

- Locate a site for the potential absorption field.

- Dig a minimum of four holes — at least three holes around the perimeter of the absorption field and one in the middle of the field. This may require estimating the percolation rate to arrive at the approximate field size. Holes must be 6 to 8 inches in diameter (all the same diameter), vertical, and to the proposed depth of the trenches (18 to 30 inches deep). No power augers may be used.

- Roughen or scratch any smeared areas of the hole sides and bottoms to provide a natural soil surface for water to penetrate.

- Remove loose material from the holes and add a 2-inch layer of 1/4- to 3/4-inch washed rock into the bottom of holes to prevent scouring when water is added.

- Add 12 inches of water (measured from the bottom of the hole) and maintain that level for a 4-hour presoak period. This saturates the voids between soil particles with water.

Note

Watch the hole for the first 10 minutes. If the 12 inches of water completely drains away in less than 10 minutes, you can begin the percolation testing immediately. With this soil, you begin by setting the water level to 8 inches, and you can measure every 10 minutes. If 8 inches of water seeps away in less than 10 minutes, use a shorter interval. It may be easier for you to measure the amount of time it takes for water to seep 1 inch. Even with this type of soil, you may not exceed the 8-inch maximum depth.

- Twenty-four hours after the start of the presoak process, you are ready to begin the perc test measurements. This time period is required to allow intrusion of water into the individual soil particles, thus simulating wet soil conditions that can cause absorption field failure.

- Adjust the water level in each hole to an 8-inch depth, measured from the bottom of the hole. Start timing.

- At 30-minute intervals, read the drop in water level to the nearest 1/8-inch increment (1/16- inch increments are recommended).

- Replace water up to the 8-inch depth.

- Continue reading at 30-minute intervals, then replacing water to 8 inches above the hole bottom until you have three consecutive readings within 10 percent of the previous reading.

- If the percolation rates of the holes are within the required 10 to 60 minutes per inch range, design the absorption system based on the hole with the slowest perc rate.

- If the percolation rates are not within the required 10 to 60 minutes per inch range, or if the perc rate of the slowest hole varies more than 20 minutes per inch from any of the others, the site must be evaluated by a registered soil scientist.

Percolation tests

Percolation, or "perc," tests are best suited for sites that do not have significant groundwater pollution potential. In Missouri, perc tests for sewage systems requiring Department of Health permits may only be conducted by registered engineers, geologists, sanitarians, soil scientists or other persons who have received Department of Health training and certification. Results of these tests are only accepted for design purposes if the percolation rates (measurements of how fast water drains from holes in your soil) are between 10 and 60 minutes per inch. If perc rates are outside this range, a soil morphology evaluation must be used to size the absorption field. Table 2 shows the minimum absorption field area needed based on various percolation rates. If a sewage system permit is not required, you may follow the steps listed in the "Percolation test procedure" section for conducting a percolation test.

Table 2

Minimum absorption field area based on percolation rate

| Percolation rate inch | Absorption area per bedroom | Loading rate per square foot1 |

|---|---|---|

| less than or equal to 10 minutes2 | 150 square feet | 1.0 gallon |

| 11 to 30 minutes | 200 square feet | 0.8 gallon |

| 31 to 45 minutes | 265 square feet | 0.45 gallon |

| 46 to 60 minutes3 | 300 square feet | 0.4 gallon |

| 61 to 120 minutes3,4 | 600 square feet | 0.2 gallon |

1Gallons of sewage tank effluent per day per square foot of trench bottom.

2Soils with percolation rates of 1 to 10 minutes per inch or less shall either be evaluated for severe geological limitations by a registered geologist, or a soil morphology examination shall be required.

3When percolation rate is greater than 45 minutes per inch, backfill above infiltration barrier shall be sand, loamy sand, or sandy loam, when available. Two to 4 inches of loamy soil shall be used to cap the sandy backfill to keep rainwater from entering the system.

4When percolation rate is greater than 45 minutes per inch, backfill above infiltration barrier shall be sand, loamy sand, or sandy loam, when available. Two to 4 inches of loamy soil shall be used to cap the sandy backfill to keep rainwater from entering the system. Sewage system must be designed and approved by a Missouri registered engineer.

Septic tank components

Septic tanks are constructed of many materials, including reinforced concrete, fiberglass or metal. The tank may contain up to three compartments. Most important is that the septic tank must be watertight to prevent leakage of untreated sewage that might pollute groundwater and to prevent leakage of groundwater into the tank that could overload the absorption field.

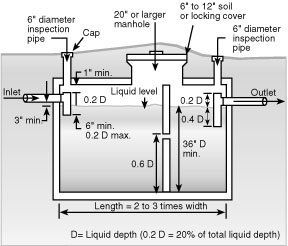

Figure 2

Figure 2

Typical components of a reinforced concrete septic tank.

Reinforced concrete tanks, the most common, are built using one of three configurations: mid-seal, top-seal or monolithic cast. The mid-seal tank is cast in two nearly identical halves that are joined together with a sticky, tar-like mastic sealant. The top-seal tank is formed into a one-piece tank portion with a concrete lid secured to the open top with mastic sealant. The monolithic cast tank is factory-formed as one unit, making it more watertight but more expensive than the other two types of concrete tanks.

Fiberglass or composite plastic tanks offer a near-perfect watertight seal. These tanks may cost more than concrete tanks and require extra care when installing on sites with rocky fill material that could damage the tank.

Metal sewage tanks are not to be used unless specifically allowed by the regulatory agency on a case-by-case basis, and then should be used only if they are covered inside and outside with a bituminous coating. Even with such a coating, metal septic tanks are prone to corrosion and subsequent collapse.

In all septic tanks, the inlet and outlet pipes should be at least 4-inch diameter Schedule 40 PVC, cast-iron or other approved pipe and be protected by baffles or sanitary tees made of acid-resistant concrete, acid-resistant fiberglass or plastic. The baffles or tees ensure that floating scum from the tank doesn't plug the absorption field or inlet pipe. Six-inch diameter inspection pipes should be located above the baffles or tees and extend to the top of the ground surface. These pipes are for checking solids levels and clogs and should be capped when not in use. A 20-inch or larger square or round manhole should be installed in the cover of the tank over each compartment to provide access for agitation and cleaning. Extending the manhole riser to the top of the ground surface will simplify cleaning operations. Manhole openings should be covered with tight lids of heavy metal or concrete for safety purposes.

A relatively new technology, septic tank filters, are basket-like screens that enhance treatment by trapping and retaining solids in the tank. They are included with some newer septic tank designs or can be retrofitted to work with older designs through use of added manhole openings. Regular maintenance is important: These screens must periodically be removed, hosed clean with water and replaced in the tank. These devices still need to be cleaned by a service professional.

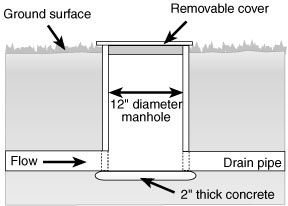

A watertight, 4-inch diameter Schedule 40 PVC pipe should connect the septic tank to the plumbing drains of the home. Slope the pipe 1/4 inch per foot (1/8 inch per foot minimum) toward the tank. Install cleanouts (Figure 3) every 50 feet (100 feet minimum) along the pipe or wherever the pipe turns corners sharper than 45 degrees.

Figure 3a

Figure 3a

Manhole cleanout for drain pipe.

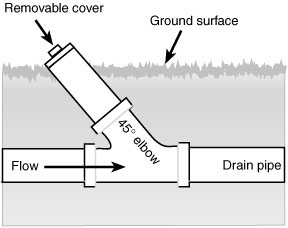

Figure 3b

Figure 3b

PVC pipe cleanout for drain pipe.

Septic tank size

Septic tanks come in rectangular, oval or round shapes. The shape of the tank has little to do with its performance, but tank size is important. The tank must retain at least two days (48 hours) of sewage flow from the house; size is based on the number of bedrooms in the dwelling. The retention capacity allows time for solids to properly separate from the liquids before the liquids pass into the absorption field. Current regulations specify a sewage quantity of 120 gallons flow per day per bedroom for design purposes. Table 3 gives a quick match of septic tank size to house size. If the dwelling has a hot tub or whirlpool, it is wise to add one bedroom of capacity for each of these fixtures present.

Table 3

Minimum septic tank sizes.

| Number of bedrooms | Minimum tank liquid capacity |

|---|---|

| 1 to 3 | 1,000 gallons |

| 4 | 1,250 gallons |

| 5 | 1,500 gallons |

For homes with more than 5 bedrooms, Tank volume in gallons = (1.5 x Daily sewage flow) + 500.

These minimum tank sizes will be adequate to handle all household wastes, including water from the toilet and kitchen drains, referred to as blackwater, and water from the bathtub, shower, sinks and laundry, which is called graywater. Larger tanks allow longer intervals between tank clean-out operations.

If a lift-station pump will be installed in the septic tank to allow pumping to an upslope absorption field, the regulatory agency may require the next size larger tank to offset the displacement volume of the pump.

Closing an abandoned septic system

To decrease the risk of personal injury or environmental harm from a septic system that is no longer in use, it is important to take the following steps. First, the septic tank should be pumped by a qualified service professional so that effluent will not seep into the environment of that human contact is minimized. The tank should then be removed and the hole filled with soil. Alternatively, the tank should be filled with coarse aggregate or sand. The riser should then be collapsed and filled with soil.

Sizing the absorption field

Important

If your septic tank/absorption field system has not been designed according to the capacities of the soil in the field area, the system will not function properly no matter how good the construction. This section shows typical calculations involved in sizing an absorption field system using the two methods described in the "Determining soil suitability" section.

Using soil morphology results

Example: A state-approved soil scientist evaluates the soils exposed in several backhoe pits. The soils are determined to be of Soil Group III, with a silty clay loam texture with low to moderate shrink-swell potential, and prismatic soil structure. A backhoe with a 2-foot wide bucket will be used to dig the trenches to serve a 3-bedroom home with a conventional septic tank/absorption field system.

- From the DOH sewage standards manual, a single-family home produces 120 gallons per day per bedroom. So 120 gallons per day per bedroom x 3 bedrooms = 360 gallons per day flow.

- From the DOH manual, the soil described above has an allowable application rate of 0.3 gallons per day per square foot of absorption field.

- 360 gallons per day ÷ 0.3 gallons per day per square feet = 1,200 square feet of absorption area.

- 1,200 square feet ÷ 2 feet. width = 600 lineal feet of trench.

- Laterals cannot exceed 100 feet in length, so

600 lineal feet ÷ 100 lineal feet per trench = 6 trenches needed.

Using percolation test results

Example: Four perc holes are dug and the perc rate is measured in minutes per inch (mpi), with the following results: #1 = 28 mpi, #2 = 36 mpi, #3 = 47 mpi, #4 = 31 mpi. A backhoe with a 2-foot wide bucket will be used to dig the trenches to serve a 3-bedroom home with a conventional septic tank/absorption field system.

- Use the slowest of the four perc rates for sizing the absorption field = 47 mpi.

- From the DOH sewage standards manual, a 47 mpi perc rate requires 300 square feet of absorption area per bedroom, so 300 x 3 = 900 square feet of absorption area.

- 900 square feet ÷ 2-foot width = 450 lineal feet of trench. Laterals cannot exceed 100 feet in length, so 450 lineal feet ÷ 90 lineal feet per trench = 5 trenches needed.

Installing the absorption field

Construction of the absorption field should be done when the soil is crumbly — never wet. Construction in wet soil causes puddling, smearing and soil compaction, which reduces soil permeability and can contribute to system failure. If occasional soil smearing does occur, scratch or rake those soil surfaces when dry to re-expose the natural soil characteristics.

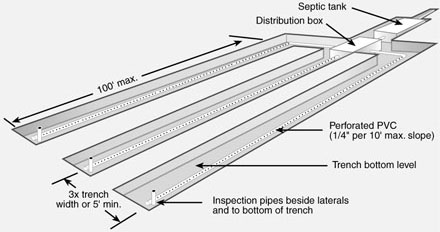

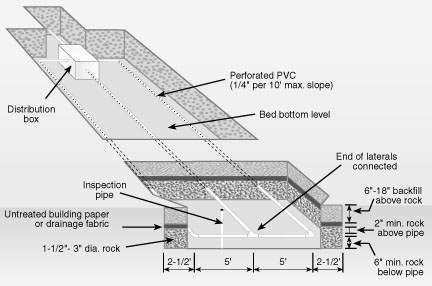

The absorption field may be arranged in trenches or a bed. Trenches are preferred for flat and sloping sites because they allow the sewage more sidewall contact with the soil. Beds work best on sites with up to 5 percent slope and on smaller lots that do not have room for trenches. Trenches laid on sites with 4 percent or more slope must be installed along the contour. Use of a builder's level or transit is critical for such applications. Examples of trench and bed layouts are shown in Figures 4 and 5.

Figure 4

Figure 4

View of a typical absorption trench field.

Figure 5

Figure 5

View of a typical absorption bed.

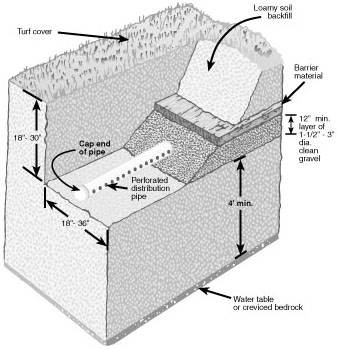

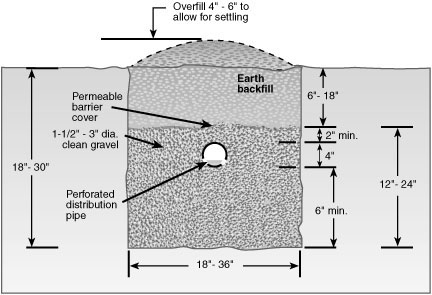

The absorption trench should be 18 to 36 inches wide and 18 to 30 inches deep. If a trench or bed depth of less than 18 inches is specified by the results of a soil morphology evaluation, "shallow placement" procedures should be followed ("Shallow placement of trenches" section). The recommended vertical separation distance between the bottom of the absorption field and any limiting layer, such as a fragipan, creviced bedrock or seasonal high water table is 2 feet or more for standard systems. Contact your county regulatory agency for the specified separation distance on your site. Trench construction using cherty clay soils located in areas of severe geological limitations must have less than 50-percent rock fragments and a vertical separation distance of 4 feet or more between the trench bottom and seasonal high groundwater table or bedrock. Figure 6 shows these trench specifications.

Figure 6

Figure 6

View of typical trench construction dimensions.

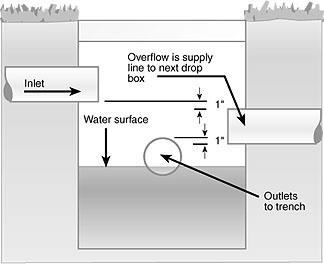

When the effluent discharges from the septic tank, it should first flow by watertight 4-inch diameter pipe through a distribution box, or "D-box" (Figure 7), and then enter the absorption field through 4-inch diameter perforated plastic pipe. Slope of the watertight pipe should be a minimum of 1/4-inch per foot toward the field to prevent clogging. Holes in the perforated pipe should be 1/2- to 3/4-inch in diameter. The lateral pipes must be of rigid construction and laid as level as possible, with not more than 1/4-inch drop in 10 feet of horizontal distance. On sloping sites, a distribution box with watertight piping to each lateral (Figure 8) is strongly encouraged over use of stepdown boxes (Figure 9), because the D-box ensures equal flow to all laterals. Use of inexpensive plastic equalizing V-notches in the D-box openings will further enhance its flow performance. Coiled black tubing that is designed for roof or basement drains is not suitable for lateral pipes.

Figure 7

Figure 7

Section view of a distribution box, or D-box.

Figure 8

Figure 8

Layout of distribution box piping on a sloping site.

Figure 9

Figure 9

Section view of a stepdown or drop box.

The absorption trench field should have at least two trenches, with a maximum trench length of 100 feet. Space the trenches a distance of three times the trench width apart, or a minimum of 5 feet on center, whichever is greater. Make the trench bottoms level, and fill the trenches at least 12 inches deep with 1-1/2- to 3-inch diameter clean, washed gravel or crushed stone. If limestone is used, all fine materials should first be screened out to prevent clogging the system. Place at least 6 inches of the gravel below the perforated pipe and 2 inches over the pipe.

Cap or plug the ends of the pipes or, when they are at equal elevations, you can connect them. Before placing soil backfill over the trenches, cover the gravel with building paper, synthetic drainage fabric, or other approved material to keep soil from clogging the gravel. Figure 10 shows the proper placement of the pipe, gravel and backfill in the trench.

Figure 10

Figure 10

Section view of an absorption trench.

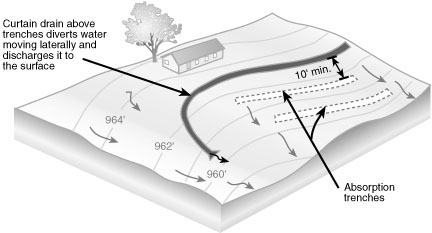

Interceptor "curtain" drains

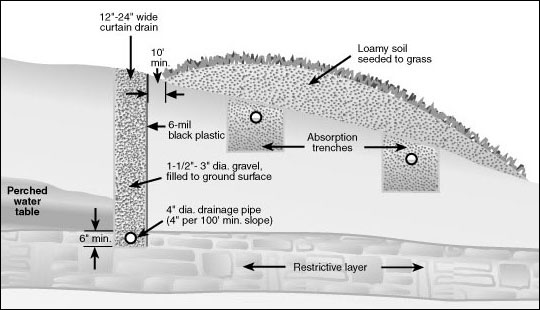

A seasonally high water table can cause saturation of the absorption field area during rainy periods, preventing sewage effluent from dispersing properly in the trenches or bed. Curtain drains intercept this surface and/or subsurface runoff and divert it around the field.

Curtain drains are dug 12 to 24 inches wide and cut a minimum of 6 inches deep into the top of the restrictive subsurface soil layer, at a distance of at least 10 feet upslope of the absorption field. Provide a minimum trench slope of 4 inches of drop per 100 feet of horizontal distance. Perforated pipe (not coiled tubing) is placed in the trench, with the holes pointed upslope toward the perched water table. Gravel fill must be brought completely to the surface so that surface runoff water may drain into the trench. If soil is placed over the surface, the interceptor drain will not perform its purpose, possibly leading to failure of the absorption system.

If the site has enough slope, the pipe outlet can be brought to ground level downslope of the absorption field and screened to allow free drainage. On level sites, pumps must be used to remove the collected water. Figure 11a and Figure 11b shows the proper placement of the curtain drain to protect the absorption field.

Figure 11a

Figure 11a

View of curtain drain location.

Figure 11b

A curtain drain diverts water around an absorption field.

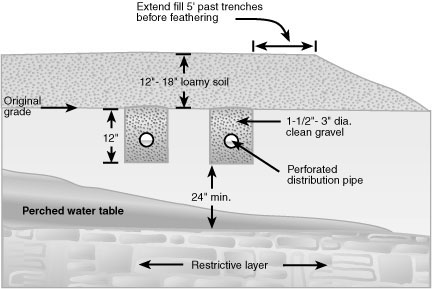

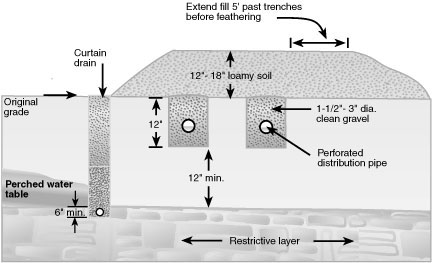

Shallow placement of trenches

Where conventional trenches cannot be used due to a seasonally high water table or lack of soil depth, "shallow placement" or "modified shallow placement" of trenches may be an option.

With shallow placement, a minimum of 2 feet of natural soil separation between the trench bottom and the uppermost elevation of the seasonally high water table or rock must be maintained. The trenches are dug to 12 inches deep and filled to the original ground level with 1-1/2- to 3-inch diameter clean gravel. The gravel is then covered with building paper, synthetic drainage fabric, or other approved material to keep soil from clogging the gravel. The absorption field is then covered with loamy soil or good topsoil to a depth of 12 to 18 inches at the center, extending the fill at least 5 feet past the trenches before feathering it down to ground level. A turfgrass cover is established on the fill immediately after construction.

With modified shallow placement, a minimum of 1 foot of natural soil separation between the trench bottom and the uppermost elevation of the seasonally high water table or rock must be maintained, and a curtain drain must be installed to divert subsurface water around the absorption field. The trenches and fill material are then finished like those of shallow placement systems described above. Figure 12 shows examples of these two types of systems.

Figure 12a

Figure 12a

Shallow placement of absorption trenches.

Figure 12b

Modified shallow placement of absorption trenches.

System maintenance

One advantage of the septic tank/absorption field system is that it has no moving parts, but it does require maintenance. Annual inspections of your septic system are recommended to ensure that it is working properly and to determine when scum and sludge in the septic tank should be cleaned out. If the scum or sludge is allowed to enter the absorption field, plugging and irreparable damage can result; when this occurs, a new septic system in a different location is the best solution. A thorough inspection includes the following steps.

- Hire a pumping contractor

Cleaning, or "pumping," should be done by a licensed and bonded professional contractor. The contractor can also check for cracked pipes and the condition of the tank baffles or tees and other parts of the system. Disposal of the septage from the tank must follow EPA Title 40 Code of Federal Regulations Part 503 (40 CFR 503). This regulation is administered in Missouri by the Department of Natural Resources. - Locate the system

If the tank access hole locations are unknown or buried, look in the basement or crawlspace of the home to see which direction the sewer pipe goes through the wall. It is usually the largest diameter pipe in the home and is typically made of plastic or cast-iron with a cleanout access. Then start probing the soil with a metal rod 10 to 15 feet from the foundation while listening for a hollow thudding sound. The tank will be at least as deep as the sewer pipe from the house. Once the system is found, make a map showing the location of the septic tank, distribution box and absorption field relative to the home and/or other permanent landmarks. Keep this information with your house records. - Uncover the access holes

Uncover the manhole and inspection ports. This may entail some digging in the yard. Make buried ports easier to service in the future by installing risers that bring the openings to ground level. These risers will serve as a reminder of the location of the system components and for regular maintenance. - Flush the toilets

Flush the toilets to confirm that the plumbing going to the system is working properly. - Measure the scum and sludge layers

Check the scum and sludge levels in the septic tank at least once a year. There are two frequently used methods for measuring the sludge and scum layers inside the tank. One method uses a clear plastic tube with a check-valve on the end can be pushed through the different layers to the bottom of the tank. When brought back up, the tube retains a sample showing a cross-section of the contents of the tank.

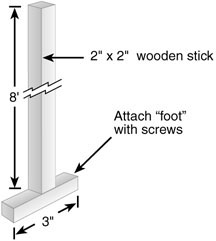

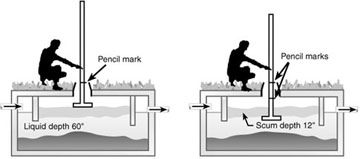

For the second method, the layers can also be measured using a long wooden stick. Attach a 3-inch long piece of wood to one end of the stick to form a "foot" (Figure 13). To measure the scum depth (Figure 14), lower the stick through the manhole until the foot rests on the mat of scum and mark the stick at the top of the tank opening. Then force the stick down through the scum layer and bring it back up until you feel resistance from the bottom of the mat. Mark the stick again. The distance between the two marks is the scum depth. Locate the lower end of the submerged tank outlet baffle or tee the same way.

Figure 13

Figure 13

Wooden stick for measuring scum and sludge depth in a septic tank.

Figure 14a

Figure 14a

Measuring the scum level in the septic tank. Left: Lower the bottom of the board to the top of the mat of scum. Mark the stick at the top of the tank opening. Right: Force the board all the way through the mat. Bring it back until you feel the bottom of the mat. Mark the stick again. The distance between these two marks is the scum depth.

Figure 14b

Figure 14b

Measuring the sludge depth in the septic tank. Left: Measure the depth of liquid and the depth of sludge. Let the stick drop until you feel resistance. Mark the stick. Right: Force the board all the way through the sludge to the bottom of the tank. Mark the stick again. The distance between these two marks is the sludge depth. If you do not know the maximum available liquid depth for your tank, measure from the bottom of the board to the wet line on the stick to find out.

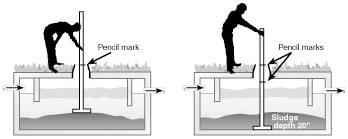

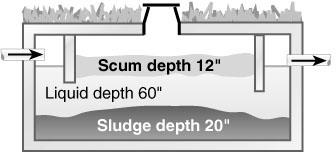

Figure 14c

Figure 14c

Determine if the tank should be cleaned. Add the scum and sludge depths. If this figure is more than half the liquid depth, clean the tank. The maximum available liquid depth in this example is 60 inches. The scum depth is 12 inches and the sludge depth is 20 inches — a total of 32 inches. Since this is more than half of the maximum liquid depth, this tank should be cleaned.

To measure sludge depth, drop the stick through the hole made previously in the scum layer until you feel resistance, then mark the stick at the top of the tank opening. Then force the stick all the way through the sludge to the bottom of the tank and mark the stick again. The distance between these two marks is the sludge depth. If the tank has a baffle in front of the outlet pipe, measure the sludge behind that baffle.

It is time to pump the tank when one of the following conditions exists:

- The bottom of the scum layer is less than 3 inches above the bottom of the outlet baffle

- The scum layer is more than 12 inches thick

- The sludge level is less than 12 inches below the bottom of the outlet baffle

- The total of the scum and sludge depths is more than half the liquid depth.

Once you know the normal sludge accumulation rate, adjust your inspection frequency accordingly.

Table 4 shows the estimated septic tank pumping frequency in years, based on tank capacity in gallons and number of people in the household. It should be remembered that garbage disposals will increase by 50 percent or more the rate at which solids accumulate in the tank and that a 1,000-gallon tank is the minimum allowable size for all new installations.

Table 4

Estimated septic tank pumping frequencies in years (for year-round residences).

| Tank size | Household size, number of people | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

| Pumping frequency, years | |||||||||

| 500 gallons | 5.8 | 2.6 | 1.5 | 1.0 | 0.7 | 0.4 | 0.3 | 0.2 | 0.1 |

| 750 gallons | 9.1 | 4.2 | 2.6 | 1.8 | 1.3 | 1.0 | 0.7 | 0.6 | 0.4 |

| 1,000 gallons | 12.4 | 5.9 | 3.7 | 2.6 | 2.0 | 1.5 | 1.2 | 1.0 | 0.7 |

| 1,250 gallons | 15.6 | 7.5 | 4.8 | 3.4 | 2.6 | 2.0 | 1.7 | 1.4 | 1.2 |

| 1,500 gallons | 18.9 | 9.1 | 5.9 | 4.2 | 3.3 | 2.6 | 2.1 | 1.8 | 1.5 |

| 1,750 gallons | 22.1 | 10.7 | 6.9 | 5.0 | 3.9 | 3.1 | 2.6 | 2.2 | 1.9 |

| 2,000 gallons | 25.4 | 12.4 | 8.0 | 5.9 | 4.5 | 3.7 | 3.1 | 2.6 | 2.2 |

| 2,250 gallons | 28.6 | 14.0 | 9.1 | 6.7 | 5.2 | 4.2 | 3.5 | 3.0 | 2.6 |

| 2,500 gallons | 31.9 | 15.6 | 10.2 | 7.5 | 5.9 | 4.8 | 4.0 | 4.0 | 3.0 |

Note

Pumping frequency can increase by 50 percent if garbage disposal is used.

Clean the tank

Cleaning should remove all scum, sludge and liquid from the septic tank. This is accomplished by pumping the liquid contents back and forth several times between the septage truck's tank and the septic tank. This agitation process mixes the scum and sludge with the liquids, allowing all solids to be removed using the truck's suction hose. Cleaning will leave a black film on the tank walls and a small amount of liquid on the tank floor. This contains sufficient numbers of bacteria to help get the tank working following the cleaning.

At this time, ask the pumper to make sure the baffles or sanitary tees are in place and working properly. Contractors attempting to clean a tank through the small 6-inch diameter inspection pipes will often leave solids in the tank and damage the baffles. Insist that the tank be cleaned through the manhole if the tank has one, even if it costs slightly more. After cleaning, it is not necessary to add yeasts, enzymes, or other "starters" or "inoculants" to get the tank working. Bacteria present in wastewater and in the tank will be adequate. Some additives can actually be harmful to the septic system and can pollute groundwater.

The most common cause of the shortened lifespan of the system is soil clogging caused by neglecting regular pumping of the septic tank. Although the average dwelling has a life of about 80 years, the useful life of an absorption field system, with proper maintenance, can be greater than 25 years. Corrosion-resistant metal tanks will last up to 10 years if properly maintained. However, the internal baffles of the metal septic tanks are not corrosion resistant and will last a maximum of 5 to 7 years before replacement is needed.

Table 5 suggests tips for extending the life of your septic tank/absorption field system.

Table 5

Maintaining your septic tank/absorption field system.

Do

- Do obtain necessary permits from the appropriate local agency before doing any construction or repairs.

- Do use professional certified installers when needed.

- Do keep your septic tank and distribution box accessible for pumping and adjustment. Install risers if necessary. The covers should be locked or of sufficient weight to prevent a child from lifting them.

- Do have your septic system inspected annually and tank pumped out every 2 to 5 years by a professional contractor.

- Do keep a detailed record of repairs, pumpings, inspections, permits issued and other maintenance activities.

- Do conserve water to avoid overloading the system. Repair dripping faucets and leaking toilets, avoid long showers and run washing machines and dishwashers only when full. Use water-saving features in faucets, shower heads and toilets.

- Do divert other sources of water, such as roof drains, house footing drains, sump pump outlets, and driveway and hillside runoff away from the septic system. Use curtain drains, surface diversions, downspout extensions, retaining walls, etc. to divert water.

- Do take leftover hazardous household chemicals to an approved hazardous waste collection center for disposal. Use bleach, disinfectants and drain and toilet bowl cleaners sparingly and in accordance with product labels.

Don't

- Don't go down into a septic tank for any reason. Toxic gases in the tank can be explosive and can cause asphyxiation.

- Don't allow anyone to drive or park over any part of the system.

- Don't cover the absorption field with a hard surface, such as concrete or asphalt. Grass is the best cover for promoting proper functioning of the field. The grass will not only prevent erosion but will help remove excess water.

- Don't plant a garden, trees or shrubbery over or near the absorption field area. Tillage may cut absorption trenches. The roots can clog and damage the drain lines.

- Don't make or allow repairs to your septic system without obtaining the necessary permits.

- Don't pour into drains any grease, cooking fats, chemical drain openers, paint, varnishes, solvents, fuels, waste oil, photographic solutions, pesticides or other organic chemicals. They can upset the bacterial action in the tank and pollute groundwater.

- Don't use your toilet as a trash can. Keep out coffee grounds, bones, cigarette butts, disposable diapers, feminine hygiene products, paper towels, facial tissues and other materials that decompose very slowly.

- Don't add enzyme or yeast additives to the septic tank in hopes of improving bacterial action. None have been proven beneficial and some actually cause damage to soil and vegetation and may pollute groundwater.

Troubleshooting

Existing septic systems may fail for a number of reasons. In addition to leaking at the soil surface, a system is failing if it is not treating the household wastewater effectively. The most common causes of system failure are from excessive water entering the system, lack of regular maintenance, or improper siting, sizing and design of the system. Diagnosing the specific cause may be difficult for the homeowner and often requires the skills of a professional. Table 6 shows common problems and their possible causes and remedies.

Table 6

Septic system troubleshooting guide.

| Problem | Possible causes | Suggested remedies |

|---|---|---|

| Sewage backs up into house and/or plumbing fixtures don't drain or are sluggish. | 1. Pipe may be clogged between house and septic tank. | a. Remove blockage with sewer routing tool. This usually is a job for a professional. b. If roots have penetrated pipe joints, reseal joints after routing or replace pipe. c. Avoid planting fast-growing trees near system. |

| 2. Scum layer may be plugging the septic tank inlet. | a. Pump the septic tank. b. Check inlet baffle or tee after pumping tank. | |

| 3. Tank outlet may be plugged by a collapsed baffle or by solids overflow. The pipe from the tank to the absorption field may be partially collapsed or plugged by tree roots. | a. Pump the septic tank. b. Route out the line and replace defective baffles, tees or pipe sections. c. Establish a regular pumping schedule. | |

| 4. Blockage that reoccurs in a new system is likely caused by improperly installed sewer line(s). | Reconstruct the sewer line(s) using the correct slope. | |

| 5. Blockage that reoccurs in a previously trouble-free system is probably caused by a broken sewer pipe connection. | Locate and replace broken pipe. | |

| 6. Excess water is entering the system. | a. Install interceptor drains to lower or divert the high water table. b. Fix water leaks and use water conservation practices. c. Replumb backwash from water softener system out of septic system. d. Check septic tank for water tightness. e. Check to see if dripline or downspout water is running onto absorption field. f. Install surface diversion where surface run-on to absorption field is a problem. g. Replumb sump pump out of septic system. | |

| 7. House sewer vent (soil stack) is plugged or frozen closed. | Clear plugged vents using a garden hose. Enlarge undersized vents. In winter, check for ice buildup on vents. | |

| 8. Lift-station pump has failed. | Repair or replace the pump. | |

| 9. Septic tank effluent filter is plugged. | Pump septic tank, then remove and clean filter. To be performed by certified professional. | |

| Sewage is surfacing in yard. | 1. Absorption field is too small. | a. Consult county health department sanitarian or Missouri Department of Health for proper size of field based on soil conditions and household sewage input. b. If undersized, enlarge the existing field or build a new one. |

| 2. Water use is excessive. | a. Install water conservation devices, such as low-flush toilets, low-volume shower heads and faucet aerators. b. Minimize use of the hot tub or whirlpool. c. Monitor water use habits of household. Check for leaks in plumbing fixtures. | |

| 3. A seasonally high water table during rainy periods saturates the soil and limits its ability to accept wastewater from the house. | a. Install interceptor drains to lower or divert the high water table. b. Use water conservation practices. c. Modify absorption field system using "shallow placement of trenches" alternatives. d. Monitor water use habits of household. Check for leaks in plumbing fixtures. e. Divert dripline and downspout water from field. f. Replumb sump pump out of septic system. g. If the site permits, build an alternative system, such as a lagoon, low-pressure pipe system, or sand mound. | |

| 4. Solids are overflowing from the tank to the absorption field. | a. Pump the tank and check the baffles or tees. b. Minimize garbage disposal use. | |

| 5. Pipe slopes or tank elevations are improper. | Rebuild absorption field on alternate site using correct pipe and trench or bed elevations. | |

| 6. Lift-station pump has failed or float switches are improperly set. | Clean septic tank, check pump (if used) and adjust float switches. | |

| Sewage odors are present indoors or there are gurgling sounds in sink or tub drains. | 1. House sewer vent (soil stack) is plugged or frozen closed. | Clear plugged vents using a garden hose. Enlarge undersized vents. In winter, check for ice build-up on vents. |

| 2. Water has been sucked from plumbing traps. | Replace water in traps by briefly running faucets. | |

| 3. Improper plumbing. | Have plumbing system checked by a professional. | |

| 4. Sewage backup in house. | Clean tank and check pump (if used). | |

| Sewage odors are present outdoors. | 1. Sewage is surfacing in yard. (See also earlier problem section.) | Repair or replace absorption field. Clean tank and check pump (if used). |

| 2. Inspection pipe caps damaged or removed. | Replace and secure damaged caps. | |

| 3. Source is from location other than homeowner's system. | Contact county health department sanitarian to investigate other potential sources. | |

| Drinking water and/or surface waters are contaminated with bacteria. | 1. Septic system is too close to well, water table or fractured bedrock; cesspool or drywell is in use; or sewage discharges to surface or groundwater. | Replace with approved septic system on alternate site. |

| 2. Well is improperly constructed. | Consult state-certified well driller or pump installer for options. | |

| 3. Water supply pipe from well is broken. | Repair piping and disinfect the entire plumbing system. | |

| 4. Source is from other than homeowner's system. | Contact county health department sanitarian to investigate other potential sources. | |

| Lift-station alarm is activated. | 1. Circuit breaker is tripped. | Check electrical connections to pump and reset the breaker. |

| 2. Pump has failed. | Make sure a professional replaces pump with proper size unit. | |

| 3. Controls are malfunctioning. | Check float switch controls and pump. | |

| Distribution pipes and/or absorption field freezes in winter. | 1. System is improperly constructed. | Have system repaired or replaced by a qualified contractor. |

| 2. There is foot or vehicle traffic over piping. | Keep people and vehicles off area. | |

| 3. The flow rate is too low from lack of use. | a. Have someone use water in house if you are away. b. Operate septic tank as a holding tank. c. Don't use antifreeze. | |

| 4. Lift-station check-valve is not working, or pump is not cycling properly. | Examine check-valve and/or replace it. Increase frequency of pump cycling. |

References

- 19 CSR 20-3.060, Minimum Construction Standards for On-Site Sewage Disposal Systems, Missouri Department of Health, February 1996.

- On-site Wastewater Treatment and Disposal Systems Design Manual, U.S. Environmental Protection Agency, 1980.

- Pipeline Newsletter, volume 6, number 3, National Small Flows Clearinghouse, 1995. Pipeline Newsletter, volume 6, number 4, National Small Flows Clearinghouse, 1995. Septic System Owner's Guide, PC-6583-S, Minnesota Extension Service, 1995.