This publication examines five areas of pesticide management practices on your farmstead:

- Pesticide storage

- Mixing and loading

- Spill cleanup

- Container disposal

- Other management

When handling pesticides, wear proper protective clothing at all times. This publication's focus is on groundwater and drinking-water protection; personal protection is not addressed. The Resources section provides some safety information sources.

Pesticide storage practices

If stored safely in a secure location, pesticides pose little danger to groundwater. Common sense suggests keeping pesticides dry and out of the way of activities that might knock over a jug or rip open a bag. Though short-term storage, such as during seasonal use, poses a lower risk than year-round storage, any storage poses a risk to groundwater.

If a spill does occur, a waterproof, or impermeable, floor, such as concrete, should eliminate any chemical seepage into the ground. Putting a curb around the floor will prevent chemicals from spreading to other areas.

Secondary containment provides an impermeable floor and walls around the storage area, which will minimize the amount of pesticide seeping into the ground if a bulk-liquid pesticide-storage tank leaks.

A mixing/loading pad provides for secondary containment during the transfer of pesticides to spraying equipment or nurse tanks.

Building a new storage facility

Building a new facility just for pesticide storage may be expensive, but generally it will be safer than trying to modify areas meant for other purposes.

When building a new facility, keep in mind a few principles of safe pesticide storage:

- Place the building 300 feet away from your well. Make the distance greater if the site has sandy soils or fractured bedrock near the land surface. The risk of pesticide contamination of groundwater is influenced by properties of both the pesticide and the soil on which it is spilled or applied.

- Contaminated surface water should drain to a properly designed storage facility and should be disposed of in a no-discharge manner.

- The mixing and loading area should be close to your storage facility to minimize the distance that chemicals are carried.

- The building foundation or secondary containment floor should be well drained and high above the water table. The subsoil should have low permeability.

- Provide pallets to keep large drums or bags off the floor. Shelves for smaller containers should have a lip to keep the containers from sliding off. Steel shelves are easier to clean than wood if a spill occurs. Store dry products above liquids to prevent wetting from spills.

- If you plan to store large bulk tanks, provide a containment area large enough to confine 125 percent of the contents of the largest bulk container plus the displaced volume of any other storage tanks in the area.

- A locked storage cabinet or building provides security. Preventing unauthorized use of pesticides reduces the chance of accidental spills. Provide signs or labels identifying the cabinet or building as a pesticide storage area. Labels on the outside of the building give firefighters information about pesticides during an emergency response for a fire or a spill.

- Provide adequate road access for deliveries and emergency equipment.

- Keep pesticides separate to prevent cross-contamination. Keep herbicides, insecticides and fungicides on separate shelves or in different areas.

- For information on other factors to consider in the design of a storage facility — such as ventilation, water access, temperature control and worker safety — contact your local University of Missouri Extension office or the MU Department of Agricultural Engineering at 573-882-2731 for plans and recommendations.

Modifying an existing storage facility

Applying the above principles can be expensive but storage improvements are a bargain compared to the cost of a major accident or a lawsuit.

The cheapest alternative may be to cut back on the amounts and types of pesticides stored. If that's not practical, consider how you can protect the pesticides you keep in storage. Sound containers are the first defense against a spill or leak.

If a container is accidentally ripped open or knocked off a shelf, confine the spill to the immediate area and clean it up promptly. The building should have a solid floor and, for liquid pesticides, a curb. The secondary containment space should be large enough to hold 125 percent of the contents of the largest full container plus the displaced volume of any other storage tanks in the area.

Remodeling existing facilities that serve other uses may be less expensive than building a new facility, but remodeling can be complicated. Using existing buildings for other activities as well as storing pesticides could compromise the safety of people and the environment. Storing chemicals in a separate facility reduces the risk associated with fire or accidental spills. Never store pesticides inside a wellhouse or a facility containing an abandoned well.

You can reduce damages by anticipating emergencies. Fires in a storage area present a special hazard to people and the environment. If containers are damaged, the stored chemicals may be carried away by water and spread over a large area.

Label windows and doors to alert firefighters to the presence of pesticides and other products stored in the structure. It's a good idea to keep a separate list of the chemicals and amounts stored. Keep a copy of the list in the house or away from the storage area, and provide a copy to local fire protection and the local emergency-response coordinator.

If a fire occurs, consider where the surface runoff water will go and where it might collect. For example, a curb around a floor can help confine contaminated water.

In making the storage area secure, also make it accessible to allow prompt removal of chemicals when needed.

Mixing and loading practices

Groundwater contamination can result even from small spills in the mixing and loading area. Small quantities spilled regularly in the same place can go unnoticed, but the chemicals can build up in the soil and eventually reach groundwater. By mixing and loading on an impermeable surface, such as concrete, you can contain and reuse most spilled pesticides.

A mixing and loading pad

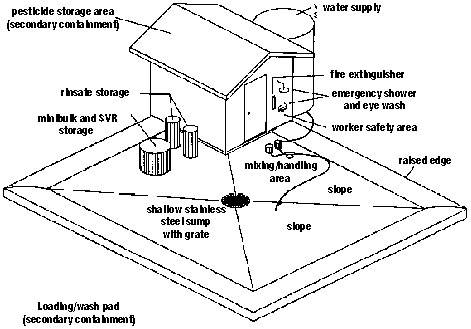

Containing pesticide spills and leaks requires an impermeable surface for mixing and loading. The pad should be large enough to contain leaks from bulk tanks, wash water from cleaning equipment and spills from transferring chemicals to the sprayer or spreader (Figure 1).

The size of the pad also depends on the equipment you use. It should provide space for washing and rinsing around the parked equipment. Having several separate rinse water, or rinsate, storage tanks keeps rinsate from different chemicals separate. That way, it can be used as mixing water on subsequent loads.

Place the pad next to the storage area. Make sure that any water from the pad moves away from the well to an approved storage facility and is disposed of in a no-discharge manner.

If you are considering building a mixing and loading pad, contact your local MU Extension office or the MU Department of Agricultural Engineering for more information.

Figure 1

Figure 1

Farm-sized pesticide facility. Source: Farm-Sized Mixing/Loading Pad and Agri-chemical Storage Facility, by D.W. Kammel and D. O'Neil, presented at the American Society of Agricultural Engineers, June 24 to 27, 1990.

Better management on your existing mixing and loading site

Spills and leaks are bound to occur from time to time. Even if you don't have an impermeable mixing and loading pad, you can minimize contamination by following some basic guidelines:

- Avoid mixing and loading pesticides near your well. One way to do this is to use a nurse tank to transport water to the mixing and loading site. Ideally, you should move the mixing site each year within the field of application.

- Avoid mixing and loading on gravel driveways or other surfaces that allow spills to sink quickly through the soil. A clay surface is better than sand.

- Install a backsiphon-prevention device on the well or hydrants to prevent reverse flow of liquids into the water supply. Never put the hose in the sprayer tank. Provide an air gap of 6 inches between the hose and the top of the sprayer tank.

- Always supervise sprayer filling. A certified applicator must supervise operations for restricted-use pesticides.

- Consider a closed handling system that transfers the pesticide directly from storage container to applicator equipment, through a hose, for example. That way, humans and the environment are never inadvertently exposed to the pesticide.

- Use rinsate for mixing subsequent loads. Spray the last rinsate load on the labeled crop.

Spill cleanup procedures

For dry spills, promptly sweep up and reuse the pesticide as it was intended. Dry spills are usually easy to clean up.

For liquid spills, recover as much of the spill as possible, and reuse as it was intended. It may be necessary to remove and field apply some contaminated soil.

The Missouri Clean Water Act (10 CSR 20–8.500) requires that spills of any amount to streams or lakes be reported. On the soil or on a mixing and loading pad, report concentrate spills greater than l quart, and dilute solutions greater than 5 gallons. Report spills of smaller quantities if they may cause damage because of the specific compound or spill location.

To report, call the Missouri Department of Natural Resources 24-hour emergency response hotline at 573-634-2436.

Remove the spilled material and contaminated soil no matter what the quantity, and dispose of it according to recommendations you receive when you report the spill.

Have an emergency-response plan for the site. Know where the runoff water will go, how to handle your particular chemicals and whom to call for help.

Container disposal practices

Unwashed and improperly stored containers can lead to groundwater contamination by allowing chemical residues to leak onto the ground. Some basic guidelines can help avoid similar problems:

- As often as possible, use returnable containers and minibulks, and take them back to the dealer.

- Pressure-rinse or triple-rinse plastic containers immediately after use because residue can be difficult to remove after it dries. Pour rinse water into the spray tank. Puncture containers, and store them in a covered barrel until you can take them to a permitted landfill or recycling center.

- Recycle plastic and metal containers whenever possible.

- Shake out bags, bind or wrap them to minimize dust and take them to a permitted landfill.

Drinking water is least likely to be contaminated if you follow appropriate management procedures or dispose of wastes in any location that is off the farm site. However, proper off-site disposal practices are essential to avoid risking contamination that could affect the water supplies and health of others.

For more information about disposal of pesticide containers and reducing the risks of burning containers, refer to MU publication WQ679 Reducing the Risk of Groundwater Contamination by Improving Hazardous Waste Management.

Other management practices

Reducing pesticide waste makes financial as well as environmental sense, but it means more than just reducing spills. It also means not buying more than you need to apply, keeping records of what you have on hand and using older products first.

Buying only what you need makes long-term storage unnecessary. You also avoid cold-weather problems, which can make some pesticides useless.

Record keeping may seem like a task unrelated to groundwater contamination, but knowing what you've used in the past and what you have on hand lets you make better purchasing decisions. Keep records of past field-application rates and their effectiveness. Along with field records, add information such as the manufacturer's name and address, chemical types and handling precautions. This information is important if you must respond quickly to an accident.

Using older products first keeps your inventory current and effective. Before using chemicals that have been stored for a few years, though, check with your local MU Extension specialist about possible restrictions on their use.

Resources

Contact your local MU Extension specialist, county health department or Natural Resources Conservation Service staff.

Be alert for local drinking-water quality and treatment and health advisories.

Read all product labels carefully for specific information on pesticide health effects.

More information about pesticides or reporting spills or possible contamination is available from these sources:

- National Pesticide Information Center, 800-858-PEST (7378) for information on recognizing and treating pesticide poisoning; pesticide products, cleanup and disposal; contacts for animal poison centers; certification and training programs; and pesticide laws

- CHEMTREC, 1-800-262-8200, chemtrec@chemtrec.com, for information about resources and solutions for hazardous materials and dangerous goods response. A 24-hour emergency information and response line is 1-800-424-9300.

- The 24-hour emergency hotline of the Missouri Department of Natural Resources, 573-634-2436.

- Missouri Department of Health and Senior Services, Bureau of Environmental Epidemiology, Jefferson City, Mo., 866-628-9891 or 573-751-6102, info@health.mo.gov.

- U.S. Environmental Protection Agency Safe Drinking Water Hotline, 800-426-4791.

- For information about recommended pesticide mixing and loading pads, contact your local MU Extension office or the MU Extension Agricultural Engineering program, 573-882-2731.

For information on proper disposal of soil contaminated by a pesticide spill, contact your local MU Extension office, or a regional DNR office listed below:

- Kansas City

816-251-0700 - Northeast (Macon)

660-385-8000 - Southeast (Poplar Bluff)

573-840-9750 - Southwest (Springfield)

417-891-4300 - St. Louis

314-416-2960

References

- Iowa State University, Midwest Plan Service (MWPS-37) 1991. Designing Facilities for Pesticide and Fertilizer Containment (No longer available online.)

- Missouri Department of Natural Resources, Rolla, Mo. Groundwater: An Economic Resource Worth Protecting.

Farm•A•Syst: Farmstead Assessment System Fact Sheet: This guide, previously named MU publication WQ676 Reducing the Risk of Groundwater Contamination by Improving Pesticide Storage and Handling, was originally produced as part of the Missouri Farmstead Assessment System — a cooperative project of MU Extension; MU College of Agriculture, Food and Natural Resources; and the Natural Resources Conservation Service — and was adapted from Wisconsin and Minnesota prototype versions of Farm•A•Syst.