Literally dozens of kinds of wood burning stoves are available. Most can be described by one of the following general categories.

- Circulating stoves

These are double walled with an inner combustion chamber usually constructed of cast iron or firebrick-lined welded steel. An outer shell of lightweight sheet metal promotes the flow of air over the inner shell. The room is heated primarily by warm air. Some units have an optional fan, which provides a more positive air flow. You obtain draft control and heat output with a damper operated by a thermostat. Burning efficiencies of 60 to 70 percent are possible with well-built units. The major advantage of the circulating unit is that during operation, the outer shell stays relatively cool. - Radiant heaters

These single walled units may be constructed of sheet metal, cast iron or welded steel. They may or may not be lined with firebrick, which improves the stove's efficiency and prolongs its life. Heat is transferred to the room directly by radiant energy and indirectly by convection currents set up by air flow over the surface of the stove unit. The early American "pot bellied stove" falls into this general category as do many of today's imported and domestic units. Draft and heat control may be automatic but are more often obtained by manually operated dampers. Radiant type heaters generally are lower in cost than the circulating units. This is not true of some of the higher-priced cast-iron units with extensive decorative features. Combustion efficiency for these units can be as high as for the circulating units. Lower efficiencies are associated with poor management of manual draft controls. - Combustion stoves

These units combine the look and feel of an open fired "Franklin Type" stove with the efficiency of a closed unit. These radiant type heaters have a door that can be opened to provide a view of the fire without adversely affecting stove operation. When the door is closed, these units operate the same as other stoves. Overall efficiencies are in the 50 to 60 percent range, depending on the amount of time units are operated in the "fireplace" mode. This compares to efficiencies of 10 to 20 percent for the usual home fireplace.

Construction

The Underwriters' Laboratories (UL) listed stove you buy will have a sheet metal, welded steel or cast iron fire box. It may also be lined with firebrick.

Sheet metal stoves are the lowest in cost and should be considered only for occasional use. Since they are light in weight, they warm up rapidly. However, extensive use leads to early burn out. Their life can be prolonged by limiting the size of fires or by lining the fire area with heavier material or firebrick. Sheet metal stoves should be examined frequently for weak, burned out spots.

Welded steel stoves are constructed of 1/4-inch thick or thicker steel plate. They warm up more slowly than sheet metal stoves, but the thicker wall section lasts longer. These units are suitable for continuous use. High quality models will have firebrick lining in the combustion area.

Cast iron has long been considered "top of the line" in wood burning stoves. It provides a stove that warms up slowly, retains heat well, does not warp and lasts for many years. However, a cast-iron stove is not more efficient than well-constructed stoves of other types. Cast iron is relatively brittle and is subject to cracking if handled roughly. For this reason, you should carefully inspect new and used cast-iron units for breaks before using them.

Firebrick or ceramic liners may be used in any of the three stove types. Liners add mass to the stove and tend to spread heat away from hot spots in the fire. This promotes more uniform heating and prolongs the useful life of the stove. Liners also lengthen the time between the starting of the fire and the heating of the room.

Sizing

Some manufacturers rate their stoves in terms of cubic feet they will heat; others use number of rooms; a few use Btu (British thermal units). Unless you know the conditions the stove was tested under and how these compare to your own situation, most ratings are of little value. At best, ratings should be used only as general guides. Selecting a size based on space available and required clearances around the stove or on capacity to handle the size fuel you have may be more important than rating.

Placing the stove

Stove placement is usually determined by location of an existing chimney flue or by the potential chimney location. The stove should be located as close as possible to the chimney inlet. Maximum length of stovepipe connecting the stove to the chimney should not exceed 8 to 10 feet, and the pipe should have no more than two 90-degree elbows.

Since wood stoves are seldom designed with positive circulation systems, locate them near the center of the area to be heated if you have a choice. Another option is to place the stove so that heat will be picked up by an existing central-heating cold-air-return system and circulated throughout the house.

Table 1. Reducing clearances from the wood burning appliance to combustible surfaces.

| Combustible surface covering | As wall protector | As ceiling protector |

|---|---|---|

| 3-1/2-inch thick masonry wall without ventilated air space | 24 inches | |

| 1/2-inch thick non-combustible insulation board over 1-inch glass fiber or mineral wool batts without ventilated air space | 18 inches | 24 inches |

| 24-gauge sheet metal over 1-inch glass fiber or mineral wool batts reinforced with wire or equivalent, on rear face with 1 inch ventilated air space | 12 inches | 18 inches |

| 3-1/2-inch thick masonry wall with 1 inch ventilated air space | 12 inches | |

| 24-gauge sheet metal with 1 inch ventilated air space | 12 inches | 18 inches |

| 1/2-inch thick non-combustible insulation board with 1 inch ventilated air space | 12 inches | 18 inches |

| 1-inch glass fiber or mineral wool batts sandwiched between two sheets of 24-gauge sheet metal with 1 inch ventilated air space | 12 inches | 18 inches |

Clearances

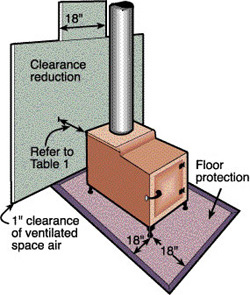

Most home fires involving wood stoves are the result of improper installation or operation. To reduce the possibility of fire, the National Fire Protection Association (NFPA) has recommended certain minimum clearances between wood stoves and combustible materials or furniture. Your local building code or homeowner's insurance company may have more stringent requirements. Table 1 shows NFPA-recommended clearance between wood stoves and protected and unprotected combustible walls and ceilings. Figure 1 illustrates these clearances and shows how protection is installed.

All floors under wood stoves (except concrete, masonry and approved non-combustible construction) must be protected from heat and coals that may fall out. This protection should extend under the stove and outward for 18 inches on all sides.

Manufacturers of listed heaters usually specify the type of material required for floor protection. The type of floor protection required for unlisted heaters depends on heater leg length. Heaters with legs less than 2 inches in height can only rest on a non-combustible floor. Heaters with legs 2 to 6 inches tall must have floor protection consisting of 4-inch hollow masonry laid to provide air circulation through the layer and covered with 24-gauge sheet metal. Heaters with legs higher than 6 inches must have floor protection consisting of closely spaced masonry that provides a thickness of not less than 2 inches. Such masonry must be covered by 24-gauge sheet metal. Instead of the requirements for floor protection specified here, a floor protector listed by a recognized testing laboratory and installed in accordance with the installation may be employed.

Legs installed by the manufacturer should not be shortened or removed, nor should any item be placed where it will interfere with circulation of air under the stove.

Connecting pipe

Stoves are connected to chimney inlets with uncovered sheet metal pipe known generally as stove pipe. This pipe is usually 6 or 8 inches in diameter and should be constructed of 24-gauge or heavier metal. (The lower the gauge number, the heavier the metal.) Select pipe size to match the outlet size of the stove.

Maximum efficiency is obtained when stovepipes are as short and as straight as possible. In no case should pipes be longer than 8 to 10 feet or contain more than two 90-degree bends.

Avoid horizontal runs. Minimum slope should be 1/4 inch per foot toward the stove. Assemble joints in the pipe so that they will funnel any liquid creosote accumulating in the pipe back to the stove where it will burn. Joints should fit tightly to eliminate entry of room air directly into the chimney system. Use furnace cement to ensure tightness. Use rivets or screws at pipe joints for added strength. A minimum of three rivets or screws is recommended at each joint.

To reduce fire potential, maintain the recommended clearances between pipes and combustibles. If the stovepipe must pass through a wall, provide an opening with at least 18 inches of clearance from all framing members. In no case should a stovepipe extend through an unoccupied area of the house. Unless listed for such connection, solid fuel burning appliances should not be connected to a chimney flue serving another appliance. You can convert a masonry fireplace chimney to use by a wood burning stove, but you can't use it as a fireplace after the conversion is made. The chimney connector must extend into the chimney above the lower point of the tile liner.

Before you buy

- Make sure the stove is listed by Underwriters' Laboratories or a similar nationally recognized testing agency that tests in accordance with U.L. Standards.

- Check with your insurance company and local building inspector to make sure you can use a wood stove without large penalties in the form of higher premiums or extensive remodeling.

- Be sure you have an economical source of fuel.

- Make sure you have access to or can install an approved chimney for your stove.

- Look at several different stove types and visit with people who are using them. Are they satisfied with performance? Have they had any problems with the unit? Has the dealer been willing to correct any problems?

- Examine stoves for quality workmanship. Are materials sturdy and parts well put together? Modern stoves gain efficiency from their ability to control combustion air. This requires an air-tight unit with close fitting parts and a tight or gasketed door.

- Shop around. Wood stoves have a "seller's market," and careful shopping may result in substantial savings for similar units.