The great variety of pesticides used in America's agricultural production system presents varying degrees of hazard. These products were made to alter life cycles of living pest organisms, and many of these products are dangerous to people if not handled properly.

The purpose of this publication is to help pesticide applicators understand and appreciate potential dangers. If an applicator uses his or her own knowledge, common sense, and the information contained in this and the other publications referred to, he or she can apply pesticides safely and effectively.

Storage of chemicals

Store pesticides in a locked and posted facility where children or other untrained people cannot get to them. Read the labels on pesticide containers for correct storage procedures. Select a storage site high enough that damage from flooding will be unlikely and downwind and downhill from sensitive areas such as houses, play areas and ponds. Pesticide storage facilities should also be located away from homes and livestock facilities to avoid or minimize contamination in case of fire.

Pesticide and expended pesticide containers are best stored in a separate building, room, or enclosure, depending on the size of the pesticide inventory. The storage area should be on the first floor to minimize contamination from a possible leaky container, and the storage area must keep the pesticides dry, cool and out of direct sunlight. The latter requirements are necessary because some pesticides are rendered useless if they become too hot or damp, if they freeze, or if they are exposed to ultraviolet radiation from the sun.

Sacks, cartons and fiberboard boxes containing pesticides should be stored on wooden pallets or on shelves off the floor. Securely lock all possible entrances to the storage area. Hang or mount weatherproof signs stating "Danger — Pesticides, Keep Out" or similar warnings over every entrance to the facility. An exhaust fan for ventilation should be used in storage rooms to reduce the temperature and high concentration of toxic fumes.

An adequate supply of water and detergent or soap is essential in the storage area. We recommend routine use of these cleaning agents by people who work with pesticides or pesticide-related materials or equipment. Also, water is a quick first aid in a poisoning emergency. Materials such as activated charcoal, vermiculite, absorbent clay, pet litter, ground corncobs or sawdust need to be readily available at the storage site to soak up spills and leaks. Hydrated lime and sodium hypochlorite (chlorinated household bleach) can be used to neutralize pesticides in an emergency. A shovel, dust pan, broom, and proper type of fire extinguisher are other essential items.

Do not store pesticides near food for human consumption, animal feed, fertilizer, seed, veterinary supplies, or other stored products. To prevent contamination or to avoid accidentally using the wrong pesticide, store different pesticides in separate locations within the storage area.

Store pesticides only in the original container, with the label plainly visible. Never store pesticides in anything used as a food or drink container, even for a short time. Storage of pesticides in such containers is a common cause of accidental poisoning.

Never provide pesticides to anyone unless that person has been properly trained or licensed. Also, make sure that the entire manufacturer's label appears on the container.

If a pesticide container becomes damaged, transfer its contents to an appropriate container. Label the new container immediately. If possible, attach the manufacturer's label from the damaged container directly to the new pesticide storage container. If you cannot salvage the old label, write the exact contents directly on the container or on a tag attached to the container.

Contact regional MU Extension specialists in your area for proper application techniques of repackaged pesticides if such information is not available. Unlabeled pesticides are worthless and dangerous, since the applicator doesn't know what they are or how to use them. They should be treated as surplus pesticides and be properly disposed of.

Preparing the sprayer

Before a spraying operation is started, rinse out the sprayer; remove and clean all nozzles, nozzle screens and strainers. Make sure strainers and nozzle screens are 50 mesh or larger when wettable powders are used. All of the nozzles should be of the same type, size and fan angle for most applications. Check all lines, valves, seals and the tank after filling the sprayer with water and during calibration to be sure there are no leaks in the spray system. For the operator's safety, replace weather-cracked or worn hoses. Adjust the nozzle height and spacing as suggested by the nozzle manufacturer or as specified on the pesticide label. These requirements differ for a given pest or crop.

Only water that is clean enough to drink should be used in the sprayer. A small amount of silt or sand in the water rapidly wears pumps and other parts of the sprayer system.

Operating a pump dry or with a restricted inlet may damage the pump. Do not operate pumps at speeds or pressures higher than the manufacturer recommends. Power take-off pumps should be restrained from rotating by chains or torque bars. Keep all shields in place. Do not use ground speeds that are too high for existing field conditions. Booms bouncing up and down or back and forth can cause application rates to vary by 50 percent. Also, such bouncing can damage the spray booms or the frame of the sprayer.

Handling and mixing

Take precautions to avoid exposure when wettable powders, dust or granules are added to the sprayer tank. When you add materials to the sprayer tank, air is forced out and carries some of the pesticide particles with it. If the solvent in the pesticide is toxic or flammable (or both), be sure the mixing operation is performed in an area where ventilation is adequate. The addition of small amounts of materials such as emulsifiers or thickeners will drastically alter the physical properties of the spray solution. Therefore, the applicator should check the pesticide label to be sure she or he is operating according to label instructions.

Many types of solvents, some of which are chlorinated, are used in the pesticide formulation processes. Vapors of chlorinated solvents are very dangerous to breathe. They can cause a "high," dizziness, or even unconsciousness. They also can cause permanent damage to the kidney, liver, and nervous system in workers exposed to the vapors for a prolonged time.

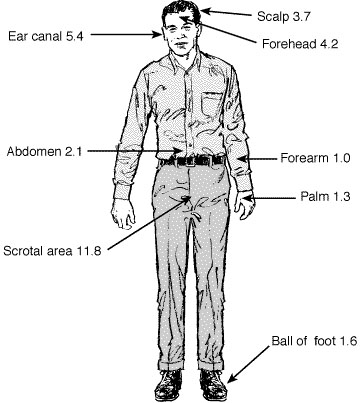

The skin on various body parts does not absorb pesticides at the same rate. Figure 1 shows dermal absorption rates based on a numerical scale in which the value of 1 for the forearm represents the lowest dermal absorption rate. That value forms the basis for assignment of values to the other body parts.

Field applications

Always be aware of the meteorological conditions existing during pesticide application. Loss of spray from a treated area increases during high winds or low humidity. In Missouri, low wind and high humidity conditions are most prevalent before 10 a.m. and after 6 p.m.

Avoid spraying near beehives, lakes, streams, pastures, houses, schools, playgrounds, hospitals or sensitive crops whenever possible. If these areas must be sprayed, do not spray during windy or low humidity conditions and always spray downwind from the sensitive area.

If possible, begin spraying in the end of the field that will permit any drift from the sprayer to be blown away from the next area to be treated. Likewise with airblast sprayers; direct the air blast from the sprayer with the prevailing wind and away from the next area to be treated. These two procedures will minimize the amount of pesticide that will be blown onto the operator. Remember, these are only guidelines and are intended to supplement the good judgment of the pesticide operator.

To minimize drift hazards, use the lowest pressure possible, the lowest boom height and the largest spray tips, and add thickeners (if the pesticide label permits) in areas where drift is likely to be particularly hazardous.

Be alert for nozzle clogging and changes in nozzle patterns. If nozzles clog or other troubles occur in the field, shut the sprayer off and move to an unsprayed area before dismounting from the sprayer to work on it. If nozzles must be cleaned in the field, use a toothbrush or a toothpick for cleaning — never a metal object. A metal object can damage the orifice in the spray tip and significantly alter the spray pattern. We recommend carrying extra spray tips on the sprayer so that plugged tips can be replaced with clean ones. Never try to unclog a nozzle by blowing through it.

Check the pesticide label for re-entry and preharvest intervals. The re-entry interval is the elapsed time after a pesticide application before workers can safely re-enter a field. The preharvest interval is the elapsed time between a pesticide application and harvest of the crop.

Equipment cleaning and storage

Trained personnel should thoroughly clean the inside and outside of mixing, loading, and application equipment immediately after use. People who clean contaminated equipment should wear proper protective clothing, including rubber boots, a rubber apron, goggles, and possibly a respirator. A specific area should be designated for cleaning operations. Use a rack or cement apron with a well-designed sump to catch contaminated wash water and pesticides. The cleanup process is important because many chemicals will rapidly corrode some metals and may also react with succeeding chemicals, thus possibly causing a loss of effectiveness.

To clean a sprayer, mix about two pounds of detergent per 40 gallons of water in the tank. Circulate this mixture throughout the bypass or agitator nozzles for 30 minutes and then drain, allowing some solution to pass through the booms or nozzles. If phenoxy herbicides such as 2,4-D, 2,4,5-T, or brush killer were used in the sprayer, rinse with an ammonia or charcoal solution.

To make an ammonia rinse, fill the tank one-third to one-half full and add two quarts of household ammonia per 25 gallons of water. Circulate the solution and allow a small amount to flow through the nozzles. Allow the remaining solution to stand overnight to neutralize any herbicide remaining in the equipment. Then pump the solution through the nozzles. After rinsing with detergent or ammonia, flush thoroughly with clean water.

When the sprayer is to be stored for a prolonged time, add one to five gallons of lightweight oil (about one gallon of oil per 40 gallons of water) before the final flushing. As the water is pumped from the sprayer, the oil will leave a protective coating on the inside of the tank, pump and plumbing.

To prevent corrosion, remove nozzle tips and screens and store them in a can of light oil, such as diesel fuel or kerosene. Close the nozzle openings with blanks to keep dirt or insects from entering the spray boom. Be sure the pump is drained thoroughly to prevent freezing. Add a small amount of oil and rotate the pump four or five revolutions by hand to completely coat the interior surfaces.

Follow directions in the owner's manual regarding the proper procedures for storing engine-equipped sprayers. Before storing the sprayer, all lines, hoses, valves and the pump should be inspected for damaged parts or leaks. Damaged parts should be replaced before the sprayer is stored.

Disposal of pesticides and containers

To avoid having to dispose of a tank load of the wrong pesticide, check out the job carefully before selecting the pesticide. After you have selected the proper pesticide, mix only enough for the particular job. Preventing a pesticide surplus is the best way to prevent a disposal problem.

Despite your best efforts, however, you cannot always avoid surplus pesticides, and you must take steps to dispose of them properly.

If you mix too much pesticide for a job, try to find other areas with the same pest problem and use any extra tank mix or rinse water on these areas. In some cases, small amounts of surplus pesticide can be diluted and reapplied to the treated area. Take extreme care to prevent excessive residues, especially with herbicides, by making sure that the total application rate does not exceed the maximum rate for which the pesticide is labeled.

To dispose of large quantities of pesticide, contact your local MU Extension center or the Missouri Department of Natural Resources (DNR) for assistance in properly disposing of excess pesticides in an environmentally safe manner.

So-called empty pesticide containers are not really empty. They still contain small amounts of pesticides, even after they have been properly rinsed. All containers, regardless of their type, should be rinsed three times before disposal. The rinse water should be dumped into the sprayer tank. Otherwise, the rinse water must be treated as a surplus pesticide and disposed of properly. Rinse water should never be dumped on the ground. Use the following rinse-and-drain procedure to prepare containers for disposal:

- Empty the container into the spray tank and drain in a vertical position for 30 seconds.

- Refill the container one-fifth to one-fourth full with rinse water or other recommended solution.

- Rinse thoroughly, pour into the spray tank and drain in a vertical position for 30 seconds.

- Repeat steps 2 and 3 until the container has been rinsed three times.Empty the container into the spray tank and drain in a vertical position for 30 seconds.

Rinsed containers should not be used for any other purposes except where the label allows the container to be reused or recycled.

Disposal of any pesticide container or pesticide-related waste by open dumping or open burning is illegal. Although empty containers that have been properly cleaned can legally be placed in a sanitary landfill, recycling in one of the container recycling programs is the preferred method of disposal. The Missouri Solid Waste Management Law and rules prohibit dumping or burying of waste such as empty containers on one's property. For assistance in disposing of rinsed containers, contact the Missouri Department of Natural Resources Hazardous Waste Program.

Pesticide containers that are not empty cannot be accepted at a sanitary landfill. Some of these waste pesticides are classified as hazardous waste and must be managed according to the Missouri Hazardous Waste Management Law and rules. For specific information on these requirements, contact :

- DNR Pollution Unit

PO Box 176

Jefferson City, Mo. 65102

800-361-4827.

Spilled materials

Should an accidental spill occur, follow these easy steps to clean up the spilled pesticide safely:

- Control the spill by stopping the source of the spill. For example, if the spill is due to a broken hose, close the valve or temporarily patch the hose to stop the leak. (Remember to use the appropriate personal protective equipment when doing this.) If the source of the spill is a container leak, place the leaking container in a larger, watertight container.

- Contain the spill so that it does not spread and get into water sources. This can be done by building a levy around the spill with materials that are specially designed to stop pesticide spills from spreading. Containment materials are available from chemical dealers and should be kept on hand in case of an emergency.

- Clean up the spill immediately. Absorbent materials like ground corncobs, pet litter or sawdust should be spread on the spill area to soak up the pesticide. Next, the contaminated material must be shoveled into a leakproof container for proper disposal. Do not flush the area with water or use a cleaning solution until talking with trained personnel; this will help avoid the risks of chemical reaction and groundwater contamination.

- Call the Department of Natural Resources at 573-634-2346 to report any spill and to find out what, if any, reports need to be filed, and for any technical assistance. They will be able to identify what safety steps are necessary to thoroughly decontaminate the ground and how to dispose of the contaminated materials properly.

To help prevent exposure during cleanup, workers should wear the appropriate personal protective equipment. To help prevent exposure in the future, cleanup work clothes and personal protective equipment should be cleaned before work resumes. Finally, take corrective measures to help ensure that another pesticide spill will not occur.