Work-related injuries caused 416 farmer and farm worker deaths in 2017, resulting in a fatality rate of 20.4 deaths per 100,000 farm workers. The National Agricultural Tractor Safety Initiative reports that tractors cause about 50% of all farm worker deaths each year, and a 2012 study by the U.S. Department of Labor found that tractor rollovers are the most common type of tractor accident.

The U.S. Department of Labor established the Rollover Protective Structure (ROPS) Standard to address the high fatality rate associated with tractor accidents, specifically tractor overturns. Research has shown that a ROPS provides a protective zone around the tractor operator in the event of a tractor overturn. When used with a seatbelt, ROPS are 99% effective in preventing deaths and serious injuries; they are still effective without seatbelts, but the effectiveness rate is reduced.

The ROPS Standard requires rollover protective structures on all tractors manufactured after October 25, 1976 used by employees. The ROPS Standard also requires that employees receive training in nine areas of safe tractor operation; these areas are outlined below. Training shall be given at the time of initial employee assignment and at least annually thereafter.

The purpose of this guide is to assist employers and employees in training for safe tractor operation. Farm employers should review this guide with anyone who operates a farm tractor.

Safe operation

The most important point of tractor safety is knowing your tractor. Know how the tractor handles and be alert for potential dangers. A good tractor operator has read the tractor operator manual and practices the safety habits described below.

1. If your tractor has a rollover protective structure, securely fasten your seat belt.

The seat belt is intended to hold you within the safety zone of the ROPS frame if an upset occurs. The belt is there so that you will not be thrown from the tractor and crushed or receive additional injury (Figure 1). The ROPS is designed to take the total impact of tractor upset and at the same time protect you, the operator.

Do not wear a seat belt if your tractor is not equipped with a protective structure. If you do, you lose your chance of being thrown clear of the tractor in case of an upset. Buckle up and stay inside.

2. Where possible, avoid operating the tractor near ditches, embankments and holes.

Avoid holes and depressions likely to cause a sideways tractor upset. Reduce tractor speed to minimize the possibility of a sideways upset.

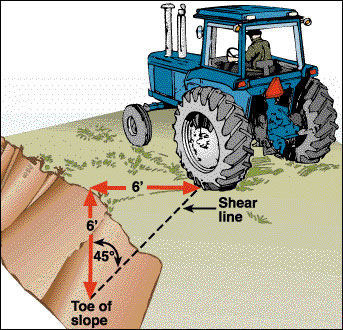

Stay away from ditches and riverbanks when possible. Look and think ahead if you must operate the tractor near ditches or riverbanks.

If you must operate near a ditch or riverbank, stay as far away from the ditch as it is deep (Figure 2). When operating around a ditch, look ahead for holes, gullies and washouts. Keeping the tractor away from ditches and river embankments can help ensure safe operation.

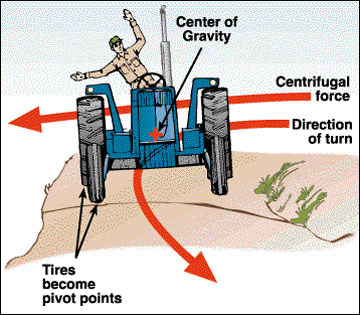

3. Reduce speed when turning or crossing slopes and on rough, slick or muddy surfaces.

Slow down before making any turn. Centrifugal force is one of the major causes of tractor upsets. The centrifugal force tries to keep the tractor going in a straight line (Figure 3). As you double the speed of a tractor while turning, the danger of upsetting is increased four times.

Reduce speed when turning with a loader. As you turn with a raised loader, you increase the possibilities of a tractor overturn. Keep the loader as low as possible, and watch for ditches, holes and rocks that might cause an upset.

If a tractor begins to slide sideways in the direction of travel, you may tip over in a ditch or run into an obstacle and upset.

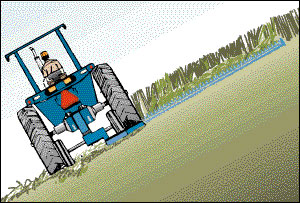

4. Stay off slopes too steep for safe operation.

Steep slopes greatly reduce a tractor’s stability. To increase stability, set the wheels at the widest setting suitable for the job you are doing. Drive slowly, avoid quick uphill turns, and watch out for holes and depressions on the downhill side and for bumps on the uphill side. If you are using side-mounted equipment, keep it on the uphill side of the tractor (Figure 4).

Keep the tractor in gear when going downhill. This allows the tractor engine to serve as a brake. If in doubt about which gear to use, select the lowest-speed gear and shift before you start downhill.

Some tractors “freewheel” and provide no engine braking in certain speed ranges. If your tractor is one of these, travel downhill using speed ranges that provide engine brake action. Check your operator’s manual for engine braking details.

5. Watch where you are going — especially at row ends, on roads and around trees.

When coming to row ends, slow the equipment down. Be alert to fencerows and make as wide a turn as possible. Apply a single brake in the direction of the turn, only doing so at a very slow speed. Quick, short, brake-assisted turns can cause upsets.

Tractor operators must follow rules of the road when operating on highways. All tractors on Missouri highways from sunset to one-half hour before sunrise must have a Slow Moving Vehicle (SMV) emblem. Occupational Safety and Health Administration regulations require any tractor operated by an employee to be equipped with a SMV emblem (Figure 5).

Missouri law also requires a tractor to be equipped with at least one white light visible from 500 feet to the front and at least one red light visible 500 feet to the rear.

Follow these driving practices on the highway:

- Maintain control of equipment.

- Stay alert.

- Wait for traffic to clear before entering the highway.

- Beware of blind intersections.

- Keep the approaching traffic lane clear.

- Don’t allow traffic to build up.

- Use hand signals or turn signals.

- Obey all traffic signs.

6. Do not permit others to ride.

Tractors are designed for only one operator and not passengers (Figure 6). Children often plead for tractor rides, but don’t give in. If you must transport passengers, use a pickup or other automobile.

7. Operate the tractor smoothly — no jerky turns, starts or stops.

When starting tractor movement, make sure no people or obstructions are ahead or behind. As you begin to move, engage the clutch slowly and evenly. Engaging the clutch suddenly, or quickly shifting a hydraulic transmission to high speed, could tip the tractor over backward — especially when towing a load or starting up a slope.

Slow down before stopping or attempting to make a turn. Fishtailing or severe braking at high speeds can cause jackknifing and rollover (Figure 7). The safest procedure is to slow down by reducing engine speed before turning. Apply both brakes if braking action is required; then, turn as wide as you can, with engine power pulling the load.

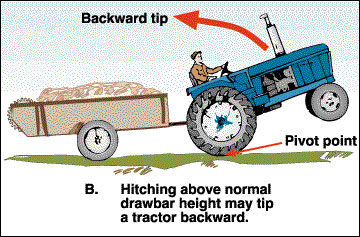

8. Hitch only to the drawbar and hitching points recommended by tractor manufacturers.

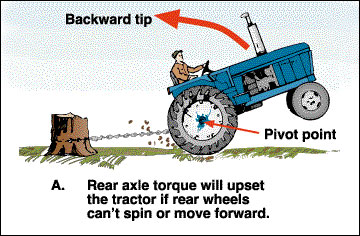

Hitching above the normal drawbar height may cause a tractor to tip over backward (Figure 8). Any time you are pulling a load with a tractor, the load is trying to pull the tractor over backward as the tractor tries to pivot around the point where its rear wheels touch the ground.

A tractor hitch has been designed to allow a tractor to pull heavy loads without the risk of a backward upset. When the hitch point on a tractor is raised, the chance for a backward upset is greatly increased. Always hitch to the drawbar and keep it as low as possible.

Always use a safety-hitch pin for fastening a pulled implement to the drawbar of a tractor. A safety pin will not bounce out, which could let the implement loose and possibly cause an accident.

9. When tractor is stopped, set brakes securely and use park lock if available.

If your tractor has a parking brake, use it. Do not depend on leaving the transmission in one of the driving gears to keep your tractor from rolling. If your tractor does not have a parking brake, then shift the transmission lever to the park position (Figure 9). This locks the transmission with positive action, keeping the tractor stationary. Make this a habit every time you leave the tractor seat: shut off the tractor, set the parking brake or shift to park, and remove the key.

Daily maintenance check

Practicing the safety hints, reading the owner’s manual and performing a daily maintenance check will increase probability of operating a tractor safely. A daily maintenance check includes the following:

- Fuel supply — enough for the job.

- Radiator water — level is within ½- to 1-inch of cap.

- Tire pressure — correct pressure for planned work; check operator’s manual.

- Tires — check for cuts or breaks in the tread and sidewalls.

- Water level in battery — into opening; use clean water.

- Transmission oil level — above add mark on dipstick; check operator’s manual for type to add.

- Air cleaner — oil to mark, as indicated in operator’s manual.

- Check for loose parts, bolts and nuts.

- Shields — make sure all shields are in place.

- Platform — clean of tools, mud, grease and any crop residue.

- Check all lighting equipment and SMV emblems.

- Check other items listed in operator’s manual at intervals stated.