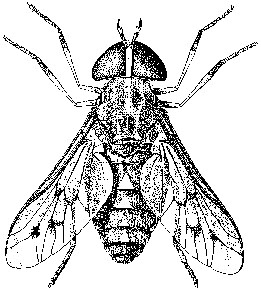

Horse flies (insect family Tabanidae) are probably the most severe fly pests of cattle on Missouri pasture and range (Figures 1 and 2). Only the females "bite," but the blood-feeding activities of these large, agile insects can constitute a serious threat to economical cattle performance when populations are large.

Figure 1

Figure 1

T. equalis. Illustration by David G. Hall in Bulletin 256 of the Arkansas Agricultural Experiment Station (1930).

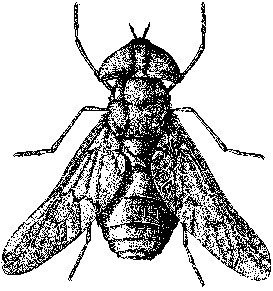

Figure 2

Figure 2

Tabanus atratus is one of the most easily recognized and notorious horse flies in eastern North America. This large, bluish-black fly with black wings can exceed 1 inch in length and inflict a very painful bite. The "blue-tailed fly" of early American ballad fame, this species readily attacks cattle, people and other hosts throughout Missouri during the summer. Illustration by David G. Hall in Bulletin 256 of the Arkansas Agricultural Experiment Station (1930).

Most Missouri horse flies have aquatic larval stages. The mother flies affix their eggs to vegetation near ponds and streams and the hatching larvae drop into the mud or water, where they live as predators for up to several years, depending on the species. When they are ready to pupate, they move from the water to terrestrial sites and generally emerge synchronously; that is, adults of a particular species all emerge at once, which facilitates mate-finding. Horse flies seem to be present all summer long. In fact, synchronous emergences result in one species being present for a time, then being replaced by another species, and so on. To cattle, however, it means being bitten the entire summer.

Female horse flies seek blood as raw material for energy and to manufacture eggs. The flies are evidently sensitive to parts of the electromagnetic spectrum that humans cannot see. Possibly their sight is like the "thermal vision" cameras used to detect heat leaks in houses. Horse flies are adept at locating warm-blooded animals; cattle, horses and similar large creatures are favored hosts. Humans are often bitten, especially around swimming pools, streams and ponds and on walks in the woods. The female fly uses her sharp mouthparts to slash a wound in the host's skin and then laps up the blood that results. This produces pain and annoyance to the host, plus economically significant blood loss when horse fly populations are large and their feeding pressure is severe. Horse flies have been implicated in transmission of cattle anaplasmosis and other blood-borne diseases in livestock.

Because most horse flies are day-feeders, it is theoretically possible to protect Missouri cattle, horses and people from attack by staying inside during daylight hours. Because this is not practical for pastured beef cattle, producers need information on control techniques that will reduce horse fly biting rates on their livestock. Recommendations useful in other areas of the world, such as moving cattle from low-lying to high pasture in the summer, are ineffective in Missouri because the state's geography is unsuitable.

Insecticidal control

The biology of horse flies is such that they are not easily controlled by insecticides. Theoretically, it would be possible to kill the larvae by poisoning ponds and streams, but this is both illegal and logistically unworkable. Because the adult flies are large, robust insects that move quickly from host to host, it is difficult to apply enough insecticide to cattle to produce control without overdosing the cattle themselves. However, field trials have demonstrated that daily treatment of cattle with synergized pyrethrins (a natural insecticide extracted from plants of the genus Chrysanthemum) will reduce biting rates by horse flies without adversely affecting cattle. Generally, this has been feasible only for dairy cattle (and for horses) because of their high management level. Few producers are capable of, or willing to, round up beef herds every day, and even if this could be accomplished, the disruption of grazing might actually result in a greater economic loss than that caused by horse flies.

This economic equation changes, however, if the cattle can be made to treat themselves. Almost 50 years ago, MU entomologists Curtis Wingo and Stirling Kyd described an economical cattle self-spraying approach that produced effective horse fly control. It will still do so today.

Insecticide to use

Obtain a concentrated pyrethrins insecticide labeled for direct application to beef or dairy cattle. For beef cattle, it should contain about 1 percent pyrethrins plus piperonyl butoxide (a synergist that improves the pyrethrins' effect). Materials labeled for dairy cattle will contain less insecticide. Appropriate formulations are sold under various trade names by farm supply or agricultural chemical firms. If you plan to treat horses, be sure that you use a formulation labeled specifically for them.

How to apply the spray

The insecticide must be sprayed on the cattle daily for best results, although partial control can be achieved by spraying it on every other day. If necessary, this can be done by hand. With horses or show cattle, it may be possible to rub or sponge the material on.

Use the insecticidal concentrate undiluted if so labeled, because a small amount of the undiluted material will give better protection than will larger amounts of spray diluted with water. On dairy cattle, the spray can be applied after the morning milking, by using a pump-up or atomizer hand sprayer. Direct the spray so that it wets the ends of the cow's hair coat and do not apply so much spray that it wets the hide, or else blistering of the skin may occur. Only a few milliliters of spray per animal are required.

On beef cattle, the only practical method of applying a spray every day is to use an automatic treadle-type sprayer. This sprayer is installed in a chute constructed in a gate or similar opening that the cattle must pass through daily. On some farms, water tanks can be fenced to provide such a situation, or watering ponds may be used. In recent years, cattle sprayers using battery or solar power have been marketed, but these all incorporate mineral or similar bait and do not exploit forced-use placement.

How to build a treadle sprayer

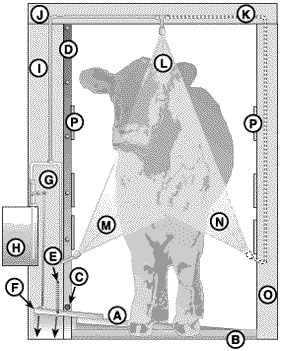

Figure 3 presents a front-view diagram of a sprayer that can be constructed by most cattle producers using readily available materials. The pump device, copper or plastic tubing, nozzles, springs and other hardware are available from most farm supply or other stores dealing in sprayer parts.

Figure 3

Figure 3

Front view of a treadle sprayer for cattle.

Construction of the sprayer described by Wingo and Kyd proceeds as follows, using galvanized metal and CCA-treated lumber wherever possible.

- Using angle iron, construct the treadle base (B) approximately 28 x 30 inches.

- Using the same type angle iron, cut a piece about 62 inches long for the upright (D). Weld this upright (D) to the treadle base (B).

- Make the treadle (A) roughly 30 x 30 x 2 inches, using solid lumber or plywood nailed or screwed firmly. Cover the treadle (A) with 1-inch-mesh welded hardware cloth, and hinge it to the treadle base (B). The treadle lever (F) is a piece of angle iron approximately 15 inches long and bolted to the top of the treadle.

- Bolt a 2 x 8 board (I) 62 inches long to the angle iron upright (D). This will serve as a base on which to mount the pump assembly.

- Mount the pump assembly (G) so that the side nozzle (M) is 16 inches above the treadle base. Note that many different types of spray pumps are available; the exact configuration of your sprayer assembly and its connection to the treadle will depend on the specific pump you use. The pump assembly includes a bracket for holding a plastic or metal container (H), which holds about a gallon of the insecticide concentrate. The nozzle should be chosen to produce a fine mist when used with the pump.

- Attach a shock spring (E) to the treadle lever and to a 2 x 8 board bolted to upright (I). The function of this spring is to raise the treadle each time after the cattle have depressed it.

- The amount of movement of the treadle is governed by a brake bolt (C) mounted in the upright (D). Set the brake bolt so that there is not more than 2 inches movement in the treadle.

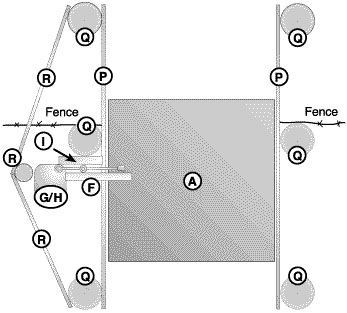

- Set posts (Q) so that the finished chute will be 3 feet wide and located in a gate that the cattle must pass through each day. Figure 4 depicts a top view of the treadle sprayer.

Figure 4

Figure 4

Top view of treadle sprayer.

- After the posts are set, install the treadle assembly described above. After this is in place, install the horizontal chute boards (P).

- A firm footing for the treadle base is necessary. If the ground is soft where you need to install the treadle sprayer, bolt 2 x 6 wood skids to the treadle base to serve as a footing.

- After installing the horizontal chute boards, set another post and install boards to make a protective rail (R). This will prevent cattle from rubbing the pump assembly and damaging it.

- Attach appropriately sized tubing (copper or plastic) to the pump assembly (G). Referring to Figure 3, route this tubing up the 2 x 8 board upright (I) to the center top board (J) of the chute. Mount the center nozzle so that it will spray directly on the backs of cattle proceeding through the chute.

- Continue the tubing (K) across the top and down the side of the chute for a lower nozzle (N) if you elect to use one. If you do not, then plug the line beyond center nozzle (L).

- Put burlap or carpet curtains on the sides and end of the chute. The bottom of the curtains should be about 20 inches above the ground. These curtains act as a windbreak to prevent the spray from being blown away before it settles on the cattle. Until the cattle get used to going through the chute, leave the end curtains off.

The treadle sprayer, properly constructed, installed and filled with an appropriate insecticide, will reduce the number of horse flies biting pastured cattle. While the pyrethrins probably kill some of the flies, the compound also acts as a repellent. The sprayer will also control horn flies and face flies, so it is not necessary to use additional treatments against these pests.

Trapping horse flies

Some cattle producers want to reduce horse flies without using any insecticide at all. In the late 1970s, MU Extension entomologist Jim Huggans tested an umbrella-type horse fly trap under Missouri pasture and range conditions and demonstrated that it could provide measurable control for a few cattle or horses.

How to build a horse fly trap

Insect traps usually function by taking advantage of the insect's behavior. With horse flies, the behaviors exploited are their tendency to "home in" on objects they perceive as hosts, plus a natural inclination to fly or crawl upward (negative geotropism). An umbrella or "Manitoba-type" horse fly trap is easily constructed, but it may require several such traps to reduce biting rates.

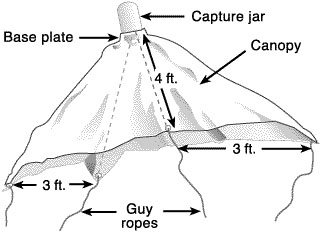

The trap consists of four panels made from plastic sheeting, plastic screening or mosquito netting. These are sewn, stapled, glued or fused into a tent shape (Figure 5). The general size of the "tent" is a pyramid about 4 feet high and 3 feet wide along each of the four bases. A grommet or ring may be attached to each lower corner to attach guy lines that hold the trap up. The "tent" canopy is supported in the center by a pole about 6 feet high (Figure 6). This pole also serves to attach the trap's "bait," which is a rubber or plastic beach ball 16 to 20 inches in diameter spray painted black. This ball is affixed to a cord and allowed to hang free under the canopy. Clothesline or other cord may be attached to rubber or plastic balls by using any of several glue-type products sold to make repairs on the soles of athletic shoes. Large copper float balls, often used in agricultural plumbing applications, are a good choice if available. When the trap is fully erected, the ball should be suspended to hang just below the bottom margin of the "tent."

Figure 5

Figure 5

Canopy assembly for construction of an umbrella-type horse fly trap. The "tent" is made from four pieces of plastic sheeting, screening or mosquito netting cut in triangles 4 x 4 x 3 feet and stapled or fused into a pyramid shape.

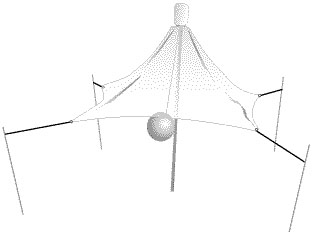

Figure 6

Figure 6

The umbrella-type horse fly trap in operation. Note how the center post holds the canopy off the ground, and how the guy lines are used like tent ropes to hold it up. The black-painted beach ball hangs just below the canopy itself.

As an alternative method of constructing the canopy frame, use three 8.5-foot lengths of electrical conduit pipe to form the legs of a tripod. Flatten the final 3 inches of one end of each pipe, drill two 3/8-inch holes through the flattened portion and bolt to the underside of the wooden base plate. (See below.) Bend the legs at a point near the edge of the base plate to form a tripod with the plate about 6 feet above the ground when the assembly is upright. Near the midpoint of each leg, drill a 1/8-inch hole, and then thread a piece of sturdy wire through each hole so that it connects each leg. The top half of this frame should be covered with plastic screen or heavy-gauge clear plastic sheeting, stapled to the periphery of the base plate and then wired or otherwise affixed to the heavy wire passing through the legs of the tripod. The "bait" ball should be hung from the center such that half the ball is below the bottom edge of the canopy covering.

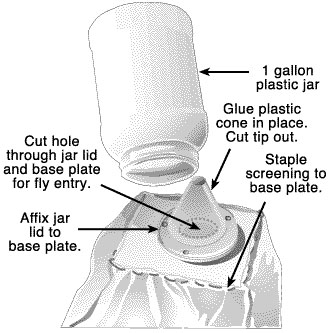

The "trap" portion consists of a 1-gallon transparent or translucent jar (such as a plastic mayonnaise jar) or container that has a metal screw ring-top and an inverted cone installed in its entrance way (Figure 7). This cone is most effectively constructed of transparent material, such as a plastic drinking cup, with the bottom cut out. The base plate can be made from an 8-inch square of plywood; the jar lid is screwed or nailed to it, and a hole is cut through the base plate and lid. The inverted cone is then glued in place inside the jar lid, and the jar is screwed upside down into its lid. See Figure 7 for details.

Cut the canopy at its apex to accommodate the plywood square and fasten the two together. The wooden post that holds the canopy up can be nailed or screwed to the underside of the plywood square.

Figure 7

Figure 7

The "trap" portion of the umbrella-type horse fly trap. Fasten a jar lid upside down on a wooden base plate. Cut a hole through the base plate and lid, and glue a plastic cone inside the lid. Replace the jar.

Using a horse fly trap

Once the trap is in operation, movement and heat radiating from the black-painted beach ball seem to attract female horse flies. In many cases, they leave cattle or horses and fly to "inspect" the ball. After discovering that it isn't a host animal, they typically fly abruptly upward and thus become caught under the trap's "tent" canopy. They usually continue crawling upward and eventually progress through the hole in the plywood base, through the inverted funnel and into the plastic jar where they cannot escape and return to the host animals. A trapping program can remove enough female flies from an area to decrease the horse fly biting rate.

The location of the trap often seems critical and best determined by trial and error. Well-traveled cattle paths, natural fly-ways through woods or brush, and livestock watering or feeding areas have been productive sites. Livestock will be curious to inspect the trap and will destroy it if they are not excluded by fencing. Barbed wire can be strung around the trap, or electric fencing will do the job. In some cases, it is possible to install the trap on a productive site just outside the cattle or horse pastures.

It is important to empty the capture jar regularly or dead flies will block the entrance. A small piece of insecticide-impregnated resin can be placed into the capture jar to kill the flies rapidly, but they will die in a day or so during midsummer. Field trials have indicated that it usually requires several such traps surrounding a pasture to afford measurable reduction in the horse fly population. Therefore, trapping horse flies may be best suited to protecting a few horses or show cattle confined to small lots or pastures.