Using manure to supply nutrients in a crop fertility program requires that manure be applied at the proper rate in terms of pounds of nutrients per acre. In addition, the manure must be applied uniformly across a field. Lush growth within and adjacent to spreader paths and lesser growth in areas between are the result of uneven spreading.

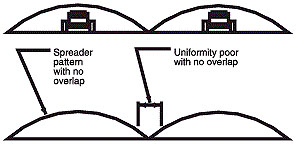

Manure spreader designers strive for an equal application rate, or uniformity over the entire width of a spreading swath. However, the application rate is nearly always greater in and near the spreader path than it is farther away.

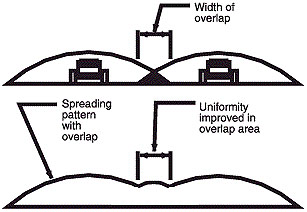

The effect of this lack of uniformity can be reduced by adjusting the distance between adjacent spreader paths so that there is some overlap of the outside areas of the spreader swath (Figure 1). The additive effect in the overlap areas tends to even out the uniformity between spreader paths (Figure 2).

Figure 1

Figure 1

Schematic of spreader pattern.

Figure 2

Figure 2

Additive effect of overlapping.

The amount of overlap, or proper distance between adjacent spreader paths, necessary for the best uniformity can be determined from a uniformity test. In this test, several plastic sheets are laid on the ground in the spreader path. The spreader passes over the sheets at normal operating speed and lane spacing. Manure collected on the sheets is weighed and compared to determine spreader uniformity.

These steps outline the procedure to determine uniformity.

- Spread a load of manure using normal lane spacing for successive spreader paths.

- Measure the distance between adjacent spreader paths and divide the distance into at least five equal parts.

- Cut five plastic sheets each at least 8 feet square and weigh each sheet in a bucket.

- Place a plastic sheet on the ground at the center of each of the five locations determined in Step 2.

- Spread manure over the sheets using the same lane spacing as in Step 1. Start spreading at least 50 feet away from the sheets.

- Pick up each sheet and fold so that no manure is lost.

- Weigh each sheet and compare the weights of manure collected to determine uniformity.

If all sheets collect about the same amount of manure, the spreader is doing a good job of distribution, and lane spacing is about right for the needed amount of overlap. If the area in and near the spreader path receives more manure than the area midway between spreader paths, then more overlap is needed and lane spacing must be reduced.

If overlap is too great — lane spacing is too close — there will be more manure collected in the areas between spreader paths. Some spreaders may spread manure at a greater rate along the outside edges of the spreading swath than in or near the spreader path. In these cases, overlap will make uniformity worse, and the best uniformity is attained with no overlap — lane spacing equals spreader swath width. It may be difficult to obtain good uniformity with some spreaders.

Table 1 outlines the steps and provides a means of recording data for the spreader uniformity test.

Table 1

Determining application uniformity

| 1. Spreader path lane spacing = _____ feet. 2. Lane spacing ÷ 5 = _____ feet. 3. Lay out five plastic sheets across area between adjacent paths. 4. Spread manure. 5. Plastic sheets: width _____ feet x length _____ feet = area _____ square feet. 6. Tare weight of plastic sheet and container = _____ pounds. | |||||

| Sheets | |||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Location | |||||

| Forward speed or throttle setting | |||||

| PTO speed | |||||

| Spreader setting | |||||

| Gross weight of plastic, manure, bucket | |||||

| Minus tare weight | |||||

| Equals manure net weight | |||||

| Divided by area of plastic | |||||

| Equals rate in pounds per square foot | |||||

| Solid and semisolid tons per acre = rate x 21.78 | |||||

| Liquid gallons per acre = rate x 5.445 | |||||

| Nutrient application rate = tons per acre x pounds nutrients per ton | |||||

| Or gallons per acre x pounds nutrient per gallon | |||||

References

- Brodie, H.L. and Smith, G.L. Calibrating Manure Spreaders. Fact Sheet 419. Cooperative Extension Service. University of Maryland.